Sand casting:

Sand casting is one of the oldest and most widely used metal casting processes, believed to have originated over 3,000 years ago

Its key benefits include low tooling cost, flexibility to produce complex shapes, suitability for small to very large components, and the ability to work with all metal alloy.

Sand casting is particularly advantageous for low- to medium-volume production and for parts where design changes or prototypes are needed quickly, making it a versatile and cost-effective choice in modern manufacturing

Sand casting

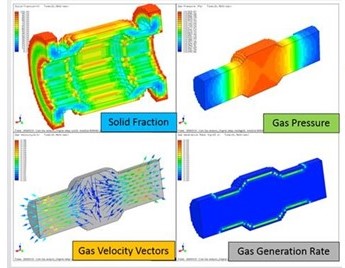

Core Gas Prediction

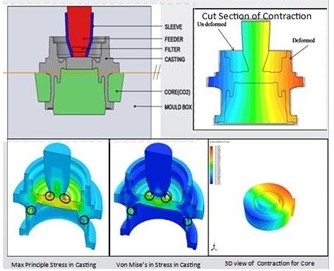

Contraction Calculation in Casting & Core

Using Casting Simulation Software ADSTEFAN, all types of sand casting and shell molding process simulation is carried out at Aganita. Using science based simulation practice, Aganita has assisted customers for prediction of casting defects; optimisation of gating / methoding; selection of suitable sleeve (with appropriate modulus extension factor –MEF), selection of type of chills- number of chills and location, and assisted to increase the yield.

Understand molten metal temperature distribution during filling of molten metal inside mold

Above animation, we can predict temperature drop of molten metal during filling of sand-casting cavity and predict any chances of cold shut/ misrun/ cold lap issues in casting

Check whether we achieve directional solidification is achieved for your gating design.

Above animation shows solidification pattern of molten metal in sand casting process. We have observed isolation during solidification which will lead to shrinkage porosity defect at isolated regions in casting.

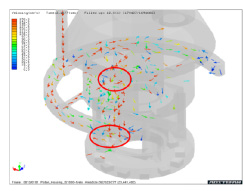

Predict molten metal turbulence inside cavity

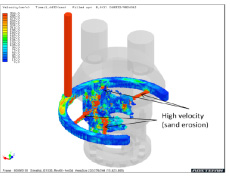

Figure above shows the velocity vectors of the molten metal in the mold. High velocity and turbulent flow is seen from casting simulation results. This clearly demonstrates the sand erosion from mold and formation of sand inclusion defect.

Figure above shows the velocity of the melt flow at the ingate. Very high velocities are observed, indicating sand erosion.

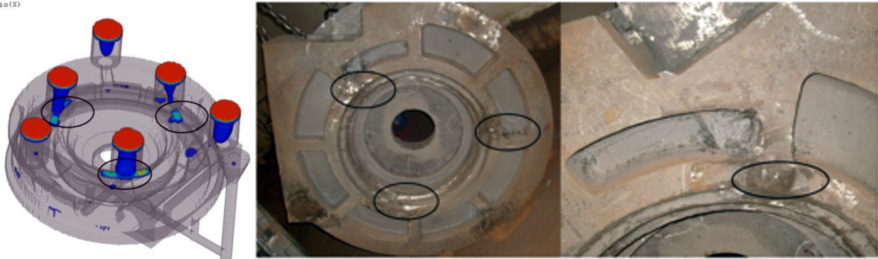

Above figure demonstrates defect mapping of shrinkage porosity casting defect for sand casting process with ADSTEFAN simulation software results. Root cause of defect is identified as improper riser/ feeder consideration . Due to this we have observed isolation during solidification is observed in cavity which leads Shrinkage porosity in casting and same phenomenon is observed in shop floor trails.