Investment Casting

Investment casting offers several advantages that make it a preferred method for producing high-precision and complex components. It provides exceptional dimensional accuracy and fine surface finish, reducing the need for extensive machining or finishing operations.

ADSTEFAN casting simulation helps investment casting by enabling engineers to predict and optimize the entire casting process before actual production.

ADSTEFAN helps optimize gating, risers, and feeding systems, ensuring complete filling of intricate geometries with minimal metal usage, which improves yield and reduces scrap.

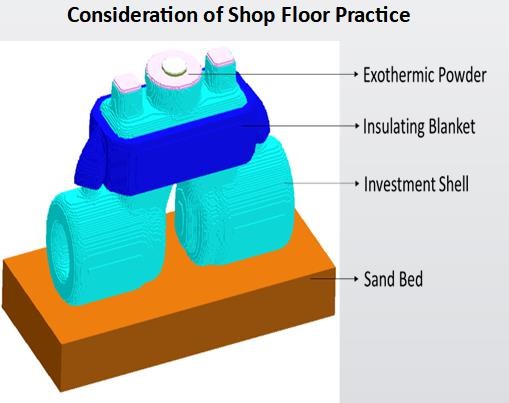

By reducing trial-and-error iterations on the shop floor, ADSTEFAN saves time, material, and cost while ensuring high- quality, dimensionally accurate components, Some of ADSTEFAN exclusive features for Investment casting.

Some of ADSTEFAN exclusive features for Investment casting

Above animation shows molten filling temperature distribution in shell for investment casting process. Through this animation, design engineer can predict temperature distribution during filling and predict chances of cold shut/ misrun/ cold lap defects in casting

Above animation shows solidification pattern in investment shell. Ideally we need to achieve directional solidification for shrinkage free casting. Above animations shown isolation during solidification and zones where isolations are identified are potential shrinkage porosity locations in castings.