Low Pressure Die Casting

Low Pressure Die Casting (LPDC) is a process in which molten metal is introduced into a permanent mold from a sealed furnace using controlled low pressure, generally between 0.3 and 1 bar.

The controlled filling and solidification provide excellent metallurgical quality, good mechanical properties, and consistent dimensional accuracy. LPDC is particularly suitable for producing complex, high- strength components such as automotive wheels, cylinder heads, and other structural parts where performance and reliability are critical.

Some of ADSTEFAN exclusive features for LPDC

Stalk Filling Consideration in ADSTEFAN

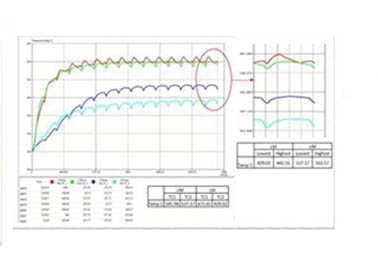

Thermal Die Stability Analysis

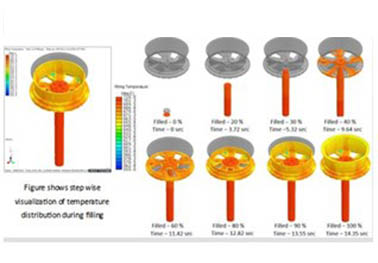

Above animation shows molten filling pattern along with stalk in LPDC process. Through this animation, design engineer can predict temperature distribution during filling and predict chances of cold shut/ misrun/ cold lap defects in casting

Above animation shows solidification pattern in LPDC . Ideally we need to achieve directional solidification for shrinkage free casting. Above animations shown isolation during solidification and zones where isolations are identified are potential shrinkage porosity locations in castings.

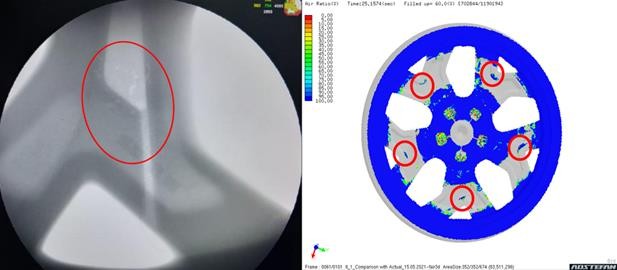

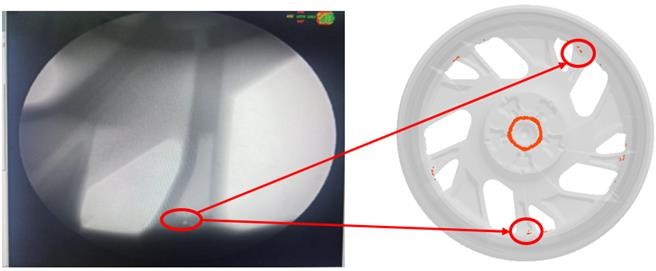

Defect corelation with actual vs ADSTEFAN Simulation results for LPDC