Understanding the Crack Casting Defect using Sand casting simulation software – ADSTEFAN

Sand casting process is known for its cost-effectiveness in producing a wide range of metal components. One of the most common defects encountered casting defect in sand casting is crack, which can compromise the structural integrity and functionality of the final product. In this article, we will discuss crack Casting defects and remedies in sand casting and also Casting crack prediction using sand casting simulation software – ADSTEFAN.

Causes of Crack Defects in Sand Casting:

- Metal Shrinkage: Metals will go through shrinkage as they solidify, leading to the formation of internal voids and stresses within the casting. If these stresses exceed the tensile strength of the material, cracks can develop.

- Thermal Stresses: During the casting process, as the metal cools and solidifies, it contracts, causing significant thermal stresses formed due to non-uniform temperature distribution in casting. If the cooling rate is uneven, casting defects such as cracks are formed.

- Inadequate Venting: Proper venting is essential to allow gases and air to escape from the mold cavity during metal pouring and solidification. Inadequate venting can result in the entrapment of gases, leading to internal pressure and crack casting defect in components.

- Design Flaws: Features in castings such as sharp corners, non-uniform section thickness, or insufficient fillets can create high stress concentration points within the casting, making it more susceptible to crack casting defect.

How ADSTEFAN – Sand Casting Simulation Software Helps to predict crack formation?

ADSTEFAN casting defect analysis technology has emerged as a powerful tool for casting crack prediction in sand casting. By sand casting simulation software, the casting process can be digitally simulated, and engineers can identify potential castings defects and implement corrective measures before physical shop floor trails. Here’s how ADSTEFAN simulation helps in casting defect prediction:

- Predictive Modeling: ADSTEFAN casting defect prediction software allows engineers to accurately model the entire casting process, including material flow, solidification, and cooling. By analyzing factors such as temperature gradients, solidification shrinkage, and stress distribution, engineers can predict the likelihood of crack formation and optimize the casting parameters accordingly.

- Gating optimization: ADSTEFAN sand casting simulation enables engineers to evaluate different mold geometries, gating systems, and venting configurations to minimize thermal stresses and ensure uniform cooling. By optimizing the gating design, the risk of crack casting defect can be significantly reduced.

- Process Optimization: Through simulation, engineers can fine-tune process parameters such as pouring temperature, pouring rate, and mold preheating to minimize thermal gradients and reduce the likelihood of crack formation.

- Casting defect prediction: In the event that cracks do occur, simulation can be used to analyze their root causes. Through optimizing the mold geometry , gating design, adjusting process parameter, simulation enables engineers to iteratively improve the casting process and eliminate crack defects.

Defect Mapping on crack defect prediction using ADSTEFAN casting simulation software:

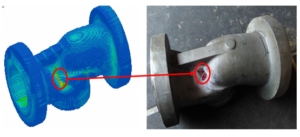

Figure (a)– Crack defect tested with Dye penetration (right side) and predicted using ADSTEFAN casting simulation (left side) in a valve body casting.

Above figure demonstrates defect mapping of crack casting defect for sand casting process with ADSTEFAN simulation software results. Observed crack defect during shop floor trials which is highlighted in above figure right hand side where Dye Penetration test is performed to determine crack location. Root cause of defect is identified as high stress concentration at crack location observed in casting in ADSTEFAN results. Due to this high stress development at highlighted location , cracks defect is formed in casting and same phenomenon is observed in shop floor trials.

In conclusion, crack defects pose a significant challenge in sand casting. Using ADSTEFAN casting defect prediction technology empowers engineers to overcome challenges with greater precision and efficiency. By using predictive modeling, optimizing mold design, and optimizing process parameters, manufacturers can enhance the quality and reliability of sand castings while minimizing the risk of crack defects.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings