Understanding Shrinkage Porosity formation in sand casting using Casting simulation software

Casting processes are prone for occurrence of casting defects such as shrinkage porosity due to various reasons such as improper gating design, process parameters etc., Understanding root cause of defect plays a vital role for defect elimination strategies. Using advanced casting simulation tools such as ADSTEFAN design engineer can understand root cause of defect formation and thus necessary preventive actions can be taken as mentioned in this article.

Shrinkage Porosity Casting defects and remedies:

As the molten metal solidifies, it undergoes volume reduction due to solidification shrinkage. If there is insufficient molten metal available to compensate for this shrinkage, voids or pores form within the casting as casting defects. The location of shrinkage porosity casting defect can vary depending on factors such as the casting geometry, gating system design, and cooling rate. Common locations include thick sections, corners, and areas farthest from the risers.

a. Shrinkage Porosity Defect in casting

Factors Contributing to Shrinkage Porosity:

Several factors contribute to the formation of shrinkage porosity defects in sand casting, including:

- Gating Design and Venting: The design of the gating design plays a critical role for proper metal flow and directional solidification. Improper solidification of metal and feeder design, leading to the formation of shrinkage porosity defects. Proper gating optimization should be performed well before actual production trials by using advanced sand casting simulation software tools such as

- Cooling Rate: The rate at which the metal cools within the mold influences the size and distribution of shrinkage porosity casting defects. Rapid cooling can enhance shrinkage porosity issues, while controlled cooling techniques can help minimize their occurrence.

- Process Parameters: Variables such as pouring temperature and cooling time significantly impact the solidification behavior of the metal and, consequently, the likelihood of shrinkage porosity formation.

Addressing shrinkage porosity prediction with casting methods simulation Software:

Casting mold flow simulation software has emerged as a powerful tool for predicting and mitigating shrinkage porosity casting defects in sand casting. By using advanced computational modeling techniques, engineers can simulate the entire casting process virtually, gaining insights into the behavior of molten metal as it fills the mold and solidifies.

Key benefits of casting method design software for shrinkage porosity prediction include:

- Predictive Modeling: Sand casting simulation software allows engineers to simulate the solidification process and shrinkage porosity prediction. By identifying potential problem areas in the casting design or process parameters, engineers can redesign gating system to minimize defects.

- Gating Optimization: Through iterative simulations, engineers can perform Gating Optimization to improve metal flow, minimize turbulence, and enhance venting efficiency. By fine-tuning gating systems, manufacturers can reduce the risk of shrinkage porosity casting defects and casting rejection reduction.

- Material Selection: casting defect simulation software enables engineers to evaluate the solidification behavior of different alloys and make informed decisions regarding material selection. By choosing alloys with favorable solidification characteristics, manufacturers can reduce shrinkage porosity issues and enhance the overall quality of the cast components.

- Process Validation: Sand casting simulation software facilitates virtual testing of process parameters such as pouring temperature, cooling rate, and pouring time, allowing manufacturers to validate their casting process before physical production. By simulating various gating systems, engineers can identify optimal process conditions that minimize shrinkage porosity defects while maximizing productivity and efficiency.

Through using casting simulation tools such as ADSTEFAN – Hitachi ICS – Japan based software, Design engineer can visualize solidification pattern of component for provided gating design and check for any isolation during solidification of metal, checking given feeder efficiency designer can determine shrinkage porosity prediction. This early detection helps design team to remodify gating design and reiterate simulations by modifying gating design

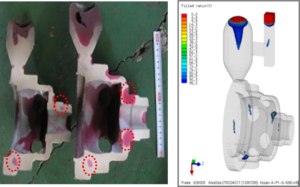

b. Defect mapping for Shrinkage porosity casting defect between ADSTEFAN results and Shop floor trials

Above figure(b) demonstrates defect mapping of shrinkage porosity casting defect for sand casting process with ADSTEFAN simulation software results. Root cause of defect is identified as isolation during solidification are observed in casting in ADSTEFAN results. Due to this isolation during solidification is observed in cavity which leads Shrinkage porosity in casting and same phenomenon is observed in shop floor trails.

Preventive action taken on component by gating optimization and process parameters optimization and thus shrinkage casting defect is controlled. This optimization is carried out in ADSTEFAN casting simulation software and best gating design are considered in shop floor trails thus leading to mitigating shrinkage porosity casting defect and remedies understanding to be followed in shopfloor. By performing corrective actions using ADSTEFAN sand casting simulation, we are able to reduce shop floor trails, production, and development time of component.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings