Understanding Shrinkage Porosity Casting defect and Casting porosity prediction using ADSTEFAN High Pressure Die Casting simulation

Introduction:

In the high-pressure die casting (HPDC) , shrinkage porosity casting defect effect quality and functionality of part. In this article, we explore the shrinkage porosity causes in high-pressure die casting and role of casting simulation software – ADSTEFAN for better understanding on how shrinkage porosity can be controlled in high pressure die casting.

While manufacturing a part in casting process, the alloy must be melted and poured into cavity. Density of a casting alloy in the molten state is less than its density in the solid state. So, alloy changes phase from the molten state to the solid state and it always shrinks in size. This shrinkage takes place when the casting is solidifying inside a die/mold and shrinkage can end up as many small voids known as ‘Shrinkage Porosity’ casting defect.

Factors Contributing to Shrinkage Porosity:

- Discontinuity during solidification: Any isolations of hot pockets of molten metal during solidification will directly results in shrinkage porosity in casting.

- Cooling Rate: Rapid cooling rates leads shrinkage porosity, particularly in thick sections of the casting.

- Design Complexity: Complex geometries and thin walls, creating localized cooling differentials and promoting shrinkage.

- Alloy Composition: Variations in alloy composition influence solidification behavior, impacting shrinkage tendencies.

Strategies for Overcoming Shrinkage Porosity

- Optimize Gating and Feeding Systems: Design gating and feeding systems to promote directional solidification and minimizing shrinkage defect in casting.

- Utilization of Cooling lines: Employ advanced cooling strategies, such as Line, spot, conformal cooling and baffle systems, to regulate cooling rates and minimize temperature variations.

- Utilizing Casting Simulation Software: Using casting simulation software to predict casting defects such as shrinkage porosity prediction, air entrapment prediction, unfilling, Casting crack prediction, Casting warpage prediction , Gating optimization , process parameters optimization, and refine design iterations for enhanced casting quality.

Addressing Shrinkage Porosity with ADSTEFAN hpdc simulation software:

ADSTEFAN hpdc simulation software has emerged as a powerful tool for shrinkage porosity prediction for HPDC. By using advanced computational modeling techniques, engineers can simulate the entire casting process virtually, gaining insights into the behavior of molten metal as it fills the mold and solidifies.

Key benefits of casting simulation software in addressing shrinkage porosity include:

- Predictive Modeling: Die casting simulation software allows engineers to simulate the solidification process and predict the formation of shrinkage porosity casting defects. By identifying potential problem areas in the casting design or process parameters, engineers can perform gating optimization to minimize defects.

- Design Optimization: Through iterative simulations, engineers can optimize the design of the gating system to improve metal flow, minimize turbulence, and enhance venting efficiency. By fine-tuning gating systems, manufacturers can reduce the risk of shrinkage porosity defects and optimize casting quality.

- Material Selection: ADSTEFAN – high pressure die casting simulation software enables engineers to evaluate the solidification behavior of different alloys and make informed decisions regarding material selection. By choosing alloys with favorable solidification characteristics, manufacturers can reduce shrinkage porosity issues and enhance the overall quality of the cast components.

- Process Validation: ADSTEFAN die casting simulation software facilitates virtual testing of process parameters such as pouring temperature, cooling rate, and pouring time, allowing manufacturers to validate their casting process before physical production. By simulating various gating systems, engineers can identify optimal process conditions that minimize shrinkage porosity defects while maximizing productivity and efficiency.

Shrinkage Porosity prediction with high pressure die casting Simulation Software:

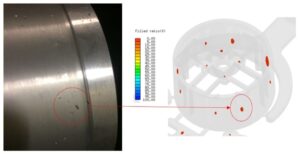

Above figure compares shrinkage porosity casting defect in a production sample with results of HPDC simulation using ADSTEFAN casting simulation software. Root cause of defect is identified as isolation during solidification observed in casting in ADSTEFAN simulation results. Once shrinkage porosity defect is predicted, and causes analysed, gating optimization is carried out using ADSTEFAN software. Using HPDC simulation procedure engineer can better understand casting defects and remedies. With this we can achieve casting yield increase by reduction of casting rejections.

Conclusion:

Shrinkage porosity casting defect pose significant challenges in HPDC, affecting the quality, reliability, and performance of cast components. However, with the use of casting simulation software, manufacturers now have powerful tools at their disposal to tackle these issues. By predictive modeling, gating optimization, and process validation capabilities, engineers can effectively tackle shrinkage porosity defects and enhance overall efficiency and quality .As the manufacturing industry continues to implement digitalization and advanced technologies, simulation software will undoubtedly play a crucial role in driving innovation and excellence in High Pressure Die Casting processes.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings