Understanding and Preventing Turbulence Filling Defects and improving Die life using ADSTEFAN – high pressure die casting simulation software

Introduction:

High-pressure die casting stands as one of the most efficient and versatile manufacturing processes, enabling the production of complex metal parts with remarkable precision. However, turbulence filling defects often emerge as a formidable challenge effecting both product quality and production efficiency. In this article, we discuss in detail turbulence filling casting defect in high-pressure die casting and how ADSTEFAN casting simulation software is a useful tool on addressing this issue.

Understanding Turbulence Filling Casting Defects:

Turbulence during the filling phase of high-pressure die casting can lead to casting defects such as air entrapment ,oxide film entrapment , incomplete filling, and surface imperfections. These defects not only affect the mechanical properties of the cast parts but also escalate production costs through reduction in die life, increased scrap rates and rework.

Root Causes of Turbulence filling:

Several factors contribute to turbulence filling casting defect analysis, including:

- Inadequate gate design leads to non-uniform metal flow.

- Improper die temperature maintained during production.

- Variations in metal properties and pouring conditions lead to turbulence phenomena.

- Insufficient venting causes trapped air pockets and oxide film entrapment.

Traditional Approaches vs. Casting Simulation Software:

Traditionally, elimination of turbulence filling defects often involved iterative trial-and-error approaches, which were time-consuming and resource-intensive which leads to increase in product development lead time, energy cost, manpower cost. However, using hpdc simulation software such as ADSTEFAN offers defect prevention and process optimization by conducting virtual trails in PC’s.

The Role of ADSTEFAN Casting Simulation Software:

ADSTEFAN die casting simulation software serves as a powerful virtual tool that replicates die casting process. By inputting process and gating parameters such as gating design consideration, alloy properties, die geometry, and process parameters, die casting simulation provide real-time insights into flow dynamics, temperature profiles, and casting defect occurrence for set gating and process parameters.

Solving Turbulence Filling Defects:

ADSTEFAN metal casting simulation software enables engineers to:

- Gating optimization: Experiment with various gate designs virtually to minimize turbulence and ensure uniform metal flow.

- Control Die Temperature: Thermal balancing die casting can be achieved by optimizing cooling/ heating lines to maintain consistent die temperatures, mitigating premature solidification and turbulence.

- Process Parameter Optimization: Simulate different process parameters to identify the optimal settings for reducing turbulence and enhancing casting quality.

Benefits of using ADSTEFAN hpdc simulation:

The adoption of ADSTEFAN casting simulation software offers benefits such as:

- Reduced Product lead development time: Minimize trial-and-error iterations during production, saving material, manpower and die modification time and accelerating product development cycles.

- Quick Decision-Making: Gain deeper insights into complex flow phenomena, facilitating data-driven decisions and process improvements.

- Enhanced Quality and Consistency: Root cause analysis of defects can be determined and immediate actions to overcome casting defects, leading to superior product quality and consistency.

Case study on prediction of turbulence filling using ADSTEFAN Casting simulation software:

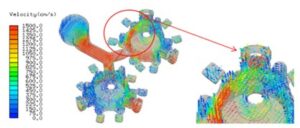

The figure above illustrates the velocity vectors results in ADSTEFAN Casting simulation software during filling of molten metal in die cavity. Die erosion defects are more likely to occur in areas with high velocity, particularly at corners and sharp edges of the die. The regions marked by red arrows indicate areas of high velocity and turbulent flow, where die erosion is most probable. By using ADSTEFAN die casting simulation, designers can visualize these high-velocity regions and Gating optimization and process parameters optimization to reduce flow velocities, thereby minimizing the risk of die erosion.

Conclusion:

For high-pressure die casting, turbulence filling defects pose significant challenges to manufacturers. However, with the ADSTEFAN die casting simulation software, casting defect prediction , prevention and gating optimization and process optimization can be performed within less time. By using casting simulation-based approaches, we can revolutionize high-pressure die casting, one can produce high reliable quality castings.

Let’s continue the dialogue and embark on a journey towards excellence in high-pressure die casting. Together, we can overcome challenges, unlock new possibilities, and redefine the standards of manufacturing excellence.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings