Speeding Up Sand Casting Simulation to Reduce Casting Development Time

Introduction:

Casting Simulation is nowadays used extensively even in small and midsized foundries in India. Using casting simulation software such as ADSTEFAN, foundries have benefitted by casting defect prediction, casting defect analysis, casting gating / methoding optimization, and faster product and process development. Such procedure has been extensively used to simulate and predict formation of defects such as air entrapment, shrinkage porosity hot tear, etc., and increase the yield and improve the casting quality.

Despite all these benefits that casting simulation tools bring to foundries, there is still an increased demand by casting buyers to develop cast products faster and supply the trial components much faster (few weeks compared to several months earlier). This calls for further steep reduction of development time. This entails that the speed of Sand casting simulation should increase drastically, and give accurate results much faster compared to what is available today.

Hitachi, makers of ADSTEFAN casting simulation software have researched on this and developed solutions to enable foundries that provide faster casting simulation solutions. Two of the solutions developed are:

- Using of parallel processing architecture to use multiple cores/ CPUs to run a casting simulation job faster

- Using General Purpose Graphics Processing Unit (GPGPU) to accelerate computing speed of sand-casting simulation.

Authors take the example of sand-casting simulation of a rotor and compare the simulation time (run time) efficiency using conventional 4 Core PC, multi-core parallel processing architecture with 32 cores, and with a GPGPU. It is demonstrated that using a GPGPU Rtx graphics card, there can be ~92% of saving in casting simulation time.

Case Study Considered: Sand Casting of a Rotor

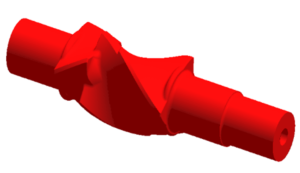

A Rotor casting to be developed using sand casting (figure 1).

Figure-1. Rotor casting model

Casting Simulation model.

A sand casting simulation model of rotor was created using ADSTEFAN software. To capture finer details, especially for the thermos-mechanical stress prediction, a fine mesh had to be used. Hence a mesh count of about 2.44 Crore elements were used in the simulation model.

- Flow analysis was carried out to visualize filling of molten metal in mold can predict temperature distribution, turbulence filling and flow related casting defects such as cold shut, misrun, blow holes, gas porosity, turbulent filling, Sand inclusion, Slag inclusion defects.

- Solidification analysis was conducted to visualize solidification pattern of casting along with methoding and gating design and understand possibility of shrinkage porosity casting defect along with location and volume of shrinkage porosity casting defect.

- We have observed very less chances of cold shut, misrun, blowholes and shrinkage porosity in casting.

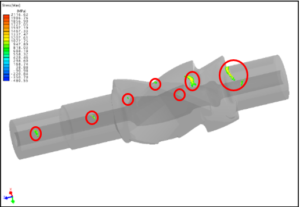

- Thermo-elastic stress analysis was conducted to predict formation of residual stress, shrinkage, cracks, warpage, high stress locations in casting during and after solidification of casting that an potentially lead to cracks in the casting. Figure-2 shows the maximum principal stress results and stress above ultimate tensile strength of 710 Mpa is highlighted in figure 2 and these regions of high stress and potential stress hot spots have been formed, and higher propensity for crack formation.

Figure-2. Crack defect in casting

During solidification, metal contracts in a non-uniform manner in the entire rotor body, causing significant thermal stresses on the surrounding sand mold.

Difference between Conventional CPUs and GPGPU

Central Processing Units (CPUs) are primary workhorses for executing computational tasks. However, as the complexity of simulations and computations has increased, CPUs have struggled to keep pace with the demand for processing power. By using parallel processing architecture, multiple processors (CPUs) can be used to speed up the simulation time for a given job. Such an architecture enables users to use large number of CPUs to speed up casting simulation time. ADSTEFAN supports parallel processing architecture and can use up to 65 CPU cores. Each of the core can execute separate simulation task. Also, multiple CPU cores can be used to speed up simulation of one large complex simulation task to speed up simulation time.

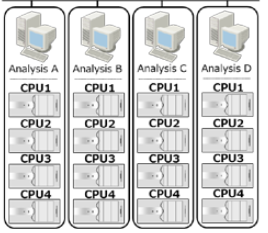

Fig 3 – Parallel computing in ADSTEFAN

Figure 3 depicts parallel computing in ADSTEFAN. Given example for 4 core licenses where user can execute 4 simulations in 4 different PC’s thus execution of 16 projects at a time is possible utilizing 4 core license.

GPGPU, graphics processing unit, is developed primarily for gaming and animation sectors. GPU comes handy to further to speed up the simulation. influences the massively parallel architecture of GPUs to perform general-purpose computations. Unlike CPUs, which do sequential processing of instructions, GPUs excel at simultaneously executing thousands parallel tasks

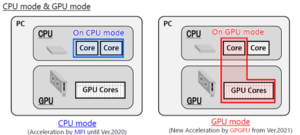

Figure – 4. CPU and GPGPU mode core utilization

This parallelism enables GPGPU to tackle computationally intensive tasks with unprecedented speed and efficiency. In conventional CPU simulations, only CPU cores are utilized for simulation activity and Graphic cord core are in ideal state. In GPGPU mode, both with CPU core and GPU core are utilized for computation and thus effective utilization of available hardware is possible in GPGPU mode.

GPGPU Function in ADSTEFAN for Sand casting simulation process:

ADSTEFAN has introduced GPGPU technology to accelerate simulation runtime and enhance user experience. By using parallel computing power of GPUs, ADSTEFAN can now handle larger and more intricate designs and simulations more efficiently.

The application of GPGPU functionality in ADSTEFAN for sand casting simulation brings forth several notable benefits:

- Accelerated Simulation Speed

- Enhanced Visualization and Interactivity

- Optimized Resource Utilization

- Future-Proofing Simulation Capabilities

Runtime Comparison Case Study:

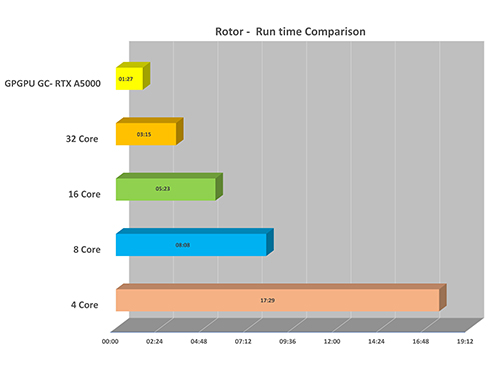

We have executed simulation using conventional 4 core, 8 core, 16 core ,32 core CPU and GPGPU mode and total simulation runtime for flow and solidification are as below Figure 4 . Hardware configuration selected is Dell workstation- Precision 3660.

Figure-5. Total runtime comparison for sand casting simulation of rotor

From above Figire-5, simulation runtime using 4 core parallel computing has taken 17 hrs. and 29 min . for simulation to complete. By using 8 Core – runtime is 08 hrs. 08 min reduced to 53% compared to 4 core and 16 core – runtime is 05 hrs. and 23 min reduction of 69% of total runtime.

By using 32 core – simulation runtime is 03 hrs. 15 min reduction of 81.4% of runtime compared to 4 core simulation. Using GPGPU with Graphic card of NVIDIA RTX A 5000 simulation runtime is further reduced to 01 hrs. 27 min – reducing runtime to 91.7% compared to 4 core simulation.

Using high end graphic card, simulation runtime can be further reduced. GPGPU function mainly depends on Graphic card configuration. As per different iterations carried on and considering cost and effectiveness, NVIDIA RTX A 5000 – with compute capability of 8.6 and Memory of 24 GB provides best results in reduction of simulation runtime.

Conclusion:

By using predictive modeling, optimizing mold design, and optimizing process parameters, manufacturers can enhance the quality and reliability of sand castings while minimizing the risk of casting defects. By using the parallel computing power of GPUs, ADSTEFAN empowers engineers and researchers to tackle complex casting challenges with unprecedented speed, accuracy, and scalability. The parallel processing capabilities of GPUs allow for the simultaneous execution of multiple simulation tasks, significantly accelerating the overall process. Tasks that would take hours or even days to complete on a CPU can be accomplished in a fraction of the time with GPGPU acceleration. As the manufacturing industry continues to evolve, GPGPU-accelerated ADSTEFAN stands prepared to drive innovation and efficiency in sand casting processes for years to come.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings