Prediction turbulence filling using Gravity Die casting simulation software – ADSTEFAN

Gravity die casting is a widely used manufacturing process that combines precision and efficiency in the production of metal components. As industries increasingly demand high-quality parts with minimal defects, understanding the filling behavior of molten metal is very critical. One of the critical aspects of this process is the prediction of turbulence during filling. In this blog, we will explore how ADSTEFAN casting simulation software helps in predicting turbulence filling in gravity die casting, enhancing the overall quality and performance of cast components.

The Importance of Turbulence in Filling

Turbulence refers to the chaotic, irregular motion of fluid particles, which can significantly impact the filling of molten metal inside mold cavity. In gravity die casting, excessive turbulence can lead to:

- Air Entrapment: When molten metal mixes with air inside mold cavity due to excessive turbulent flow, leads to gas porosity defect in casting.

- Die erosion/ Soldering defects: Due to high turbulence filling, it will directly leads to die erosion and highly impact die life cycle.

- Inconsistent Filling: Turbulent flow can cause uneven metal temperature distribution which affects solidification pattern of casting component.

Therefore, accurately predicting and managing turbulence during the filling stage is crucial for achieving high-quality castings.

Prediction turbulence filling using Casting Simulation Software

Casting simulation software plays a pivotal role in modern manufacturing by allowing engineers to visualize and analyze the casting process before production. These advanced tools simulate various parameters, including temperature, methoding design, and flow dynamics, providing insights into how molten metal behaves during filling.

Key Features of Casting Simulation Software

- Fluid Dynamics Analysis: Advanced computational fluid dynamics (CFD) models simulate the behavior of molten metal in the mold, allowing engineers to visualize flow patterns and identify potential turbulence areas.

- Parameter Optimization: Simulation software enables the testing of different parameters, such as pouring temperature and Gating optimization, to optimize the filling process and reduce turbulence.

- Defect Prediction: The software can predict potential casting defects based on the simulation results, enabling engineers to make informed design changes early in the process.

- User-Friendly Interface: Most modern casting simulation tools offer intuitive interfaces, allowing engineers to quickly learn and adapt the software for their specific needs.

By utilizing casting simulation tools like ADSTEFAN from Hitachi ICS in Japan, design engineers can evaluate the molten metal behavior during filling of mold cavity and understand possibility of turbulent filling. This early detection of turbulence allows the team to casting defect prediction in Gravity die casting and Gating optimization and process parameters optimization such as pouring rate, pouring temperature etc., can be performed in iterative way to overcome this turbulence filling behavior.

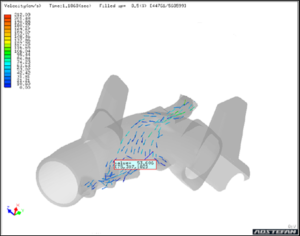

Above figure demonstrates filling velocity vector results of ADSTEFAN software. Observed filling velocity is 0.53 m/s and direction of vectors are in laminar flow. Through these results, design engineers can evaluate filling velocity which should be less than 3 m/sec in GDC process and vector directions should not be in swirling motion. Through above criteria one can predict probability of turbulent filling of molten metal in mold cavity.

Conclusion

For gravity die casting, predicting turbulence during the filling process is essential for producing high-quality components. The integration of casting simulation software into the manufacturing workflow offers a powerful tool for engineers, enabling them to visualize flow dynamics, optimize designs, and mitigate defects.

As industries continue to advance towards more efficient and accurate manufacturing processes, the role of simulation technology will help in achieving quality casting parts within lesser lead time. By leveraging these tools, manufacturers can stay ahead of the competition, delivering superior products while reducing costs and lead times.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings