Overcome Gas Porosity defect using air entrapment simulation- ADSTEFAN high pressure die casting simulation software

Gas porosity casting defect, characterized by voids or pores within cast components, is a common challenge in HPDC that can compromise product quality and performance. However, with advancements in technology and ADSTEFAN – casting simulation software, manufacturers now have powerful tools to identify and mitigate these casting defect effectively.

Understanding the Gas porosity Casting defects and remedies:

Gas porosity defects in HPDC are caused by various factors, including gas entrapment during mold filling and moisture content in die lubricants. These issues can lead to the entrapment of gas bubbles within the molten metal, resulting in undesirable voids in the final product.

Factors influence Gas Porosity defect in HPDC:

- Die Venting: Improper venting of the die can lead to the entrapment of air or other gases. If the air cannot escape from the die cavity as the molten metal fills it, it gets trapped, causing porosity.

- Die Design and Runner System: Poor die design or runner system can contribute to gas porosity. Complex geometries or sharp corners can create areas where gas can be trapped. Optimizing the die design and runner system can help minimize this issue.

- Metal Temperature and Injection Speed: Controlling the metal temperature and injection speed is crucial for minimizing gas entrapment. If the metal temperature is too high or the injection speed is too fast, turbulence can occur, trapping gas in the molten metal.

- Degassing: Inadequate degassing of the molten metal before injection can lead to gas porosity. Degassing processes remove dissolved gases from the molten metal, reducing the likelihood of gas entrapment during solidification.

- Die Temperature: Incorrect die temperatures can affect the ability of gases to escape. If the die is too cold, gases may not be able to escape properly, leading to porosity. Conversely, if the die is too hot, premature solidification can occur, trapping gases.

- Alloy Choice: Some alloys are more prone to gas porosity than others. For example, aluminum alloys may release hydrogen gas during solidification, leading to porosity if not properly managed.

Key Strategies to Overcome Gas Porosity:

- Process Optimization: Simulation software allows for the fine-tuning of process parameters such as gate design, runner layout, and injection parameters to minimize turbulence and ensure efficient gas evacuation during mold filling.

- Gating Optimization: By analyzing gas flow dynamics, engineers can optimize vent placement and design to facilitate the escape of trapped gases, reducing the likelihood of gas porosity defects.

- Die Design Optimization: Simulation tools enable the evaluation of die design factors such as part geometry, wall thickness, and cooling channel layout, helping to mitigate thermal gradients and promote uniform solidification.

- Material Selection: Through simulation, engineers can assess the impact of different alloy compositions and melt treatments on gas porosity formation, guiding the selection of alloys with reduced gas solubility.

- Defect Prediction and Analysis: Casting simulation software provides valuable insights into potential defect locations and sizes, empowering engineers to proactively address critical areas prone to gas porosity.

Air entrapment prediction using ADSTEFAN HPDC simulation software:

Casting simulation software plays an important role in the manufacturing industry, offering invaluable insights into the intricacies of the casting process. By virtually simulating the entire HPDC process, from mold filling to solidification and cooling, simulation software enables engineers to optimize parameters and predict defect formation accurately.

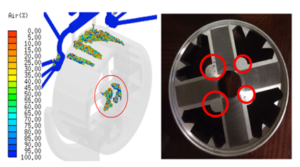

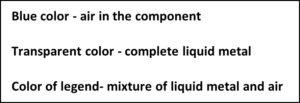

Figure (a) – Comparison with shop floor results with Air entrapment prediction done using ADSTEFAN casting simulation software

Above figure(a) displays Air entrapment prediction is done using ADSTEFAN casting simulation software and compared with actual shop floor results and found where air is entrapped in simulation, we have observed gas porosity defect in actual shop floor trials. Root cause is identified as improper venting consideration during gating system design of component.

Using this High pressure die casting simulation procedure, gating optimization and process parameter optimization can be performed in an iterative manner on computer. By optimizing gating and process parameters using ADSTEFAN simulation software, it enables design engineers to reduce shop floor trails, reduce development cycle time casting rejections reduction, resulting in casting yield increase.

Conclusion:

Gas porosity defects pose significant challenges in HPDC, but with the right tools and strategies, manufacturers can overcome these obstacles. By using casting simulation software – ADSTEFAN, die casters can perform Gating optimization, and drive continuous improvement, ultimately achieving superior quality and performance in their cast components.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings