More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings

Introduction:

Casting gating optimization is a crucial step in improving the quality and efficiency of metal castings. An optimized gating system controls the flow of molten metal into the mold, reduces defects, and minimizes waste. However, designing an effective gating system can be complex due to the many variables involved.

This is where simulation software plays the importance role. In this blog, we’ll explore how simulation tools help foundries and manufacturers optimize gating systems to achieve higher quality castings with defect free casting.

What is casting gating optimization?

The Gating system is consistent with sprue, runners and gates. Which control the flow of molten metal into the mold. A good design gating system ensure smooth flow, minimize turbulence and reduce defect inside casting.

The gating system design done by trail and error method, using simulation software help to optimize gating design with reducing time and number of trails.

How simulation software help in casting gating optimization

Simulation software helps to foundry engineers to visualize the result of how actual trails happen of mold filling and solidification before manufacturing any die or mold design we must check gating design optimization, yield improvement and defect free casting production.

- Visualize the flow patten: In this Flow pattern we are analyze the flow related result like Filling ration, filling temperature, air evacuation and filling velocity.

- Visualize the Solidification patten: In solidification pattern we are analyze the solidification direction inside the casting and we check any isolation happens inside casting and shrinkage porosity result.

- Reduce defects: Above the flow and solidification result interpretation we are find defect inside the casting by adjusting the gating geometry, engineers can eliminate common casting defect such as Air entrapment, Cold shut and misrun, Porosity related issue, Inclusion related issue

This preventive action helps to reduce defect inside casting before actual production.

- Optimizing yield: Yield is a crucial factor that directly impacts production efficiency, material utilization, and overall cost-effectiveness. A higher yield indicates minimal wastage and efficient use of raw materials, reducing the cost per casting. Optimizing yield is essential for improving profitability while maintaining quality, as excessive metal in gating and risers leads to increased energy consumption and additional machining requirements.

- Saving time and costs: Simulation software eliminates the physical conventional works and number or shopfloor trails and reduce lead time labor and raw material cost.

Case study of Valve body gating optimization for sand casting process:

In this blog we will explain with one of the case studies we have Simulated for sand casting process with material WCB. Valve body castings are integral components in various industries, particularly in fluid and gas control systems, such as in oil and gas, petrochemical, power generation, water treatment, and HVAC systems. These castings are designed to house and support the internal valve mechanism, which controls the flow, pressure, and direction of fluids or gases within a pipeline or system.

A compromised valve body can cause fluid leakage, loss of pressure, or complete system failure. In industries such as oil and gas, where high-pressure systems are common, a valve body failure could result in catastrophic leaks, fire, or even explosions, presenting a significant safety risk.

With experience customer has developed gating design with yield of 52.72% – single cavity and found after pouring shrinkage of level 3 in critical location effecting functionality of part. Aganita taken up challenge as we have explored for reduction of shrinkage porosity as well as improving yield of component.

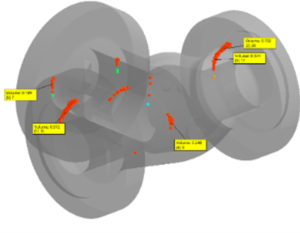

Fig 1 – Initial gating design shrinkage results of valve body casting in sand casting process

In initial gating design done by based on experience we have taken input data as 3D CAD model and pouring temperature and pouring time etc . We have simulated with ADSTEFAN casting simulation software for initial gating. The result is matching with shopfloor result with respect to shrinkage porosity in casting. Root cause is identified as improper consideration of gating and feeder locations leading to shrinkage porosity with level 3 defect.

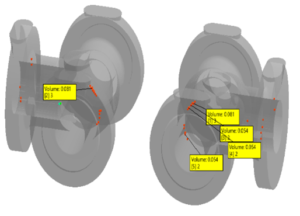

Now we have understood root cause of shrinkage porosity defect and actual feeding of hotspot through natural solidification, we have optimized gating design and placement of riser to achieve directional solidification and reduce porosity from Level 3 to Level 1 and to improve yield from 52.72% to 69.58% by changing from one cavity to two cavity.

Figure 2 – Optimized gating design shrinkage results of valve body casting in sand casting process

Observed during solidification, isolation in Initial gating design at same location where we have observed shrinkage in casting in level 3 – 100% rejection and with effective gating consideration, we have successfully reduced intensity of shrinkage to Level 1 in Optimized gating design and yield is improved from 52.72% to 69.58%.

Conclusion:

Simulation software has becoming play a game changer role for casting gating optimization in design system to reduce defects, improvement yield percentage and reduce lead time. These tools help manufacture to stay competitive and increasing demand in industry.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings