Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

INTRODUCTION

Casting is one of the oldest known manufacturing techniques and has played a significant role in the development of human civilization. The history of the casting process is long and rich, dating back thousands of years. It is used to produce a wide range of products, from small intricate components to large structural parts. Casting is a manufacturing process that involves pouring molten material, typically metal or alloy, into a mold to create a solid object of a desired shape. The molten material solidifies within the mold and takes on the form of the mold cavity.

Casting industries supply major sectors like Aerospace, Automotive, Railways, Marine, Defense, General Engineering etc. These sectors use components with stringent quality requirements as end applications of these components are safety critical and foundries/ die casting industries are working towards optimizing their manufacturing processes to meet customer requirements.

The casting process has continually adapted and evolved over millennia, leading to the production of diverse and intricate parts. It has played a crucial role in shaping human civilization by enabling the creation of tools, art, and industrial components. As technology continues to advance, casting methods are likely to become even more efficient and versatile. Now we are in Fourth Industrial Revolution where casting industries are keen to implement Machine Learning & Artificial Intelligence, Internet of Things (IoT) etc. in their production lines and converting these conventional lines into smart lines to meet customer requirements.

CASTING SIMULATION SOFTWARE:

Casting simulation software is a specialized tool used in the manufacturing industry, particularly in foundries, to simulate and optimize the casting process. The goal of casting simulation software is to predict and analyze various aspects of this process to ensure high-quality castings while minimizing defects and production costs.

BENEFITS OF CASTING SIMULATION

Simulation practice will help die casting industries in

- Reduced development costs due to least number of trials

- Less development lead time

- Less rejections

- Improved productivity

- Improved yield

- Improved casting quality

Casting simulation software is a valuable tool for foundries and manufacturers, helping foundrymen improve casting quality, reduce production costs, and minimize environmental impacts. It plays a crucial role in the design, optimization, and validation of casting processes, ultimately contributing to the efficient production of high-quality castings.

ROLE OF MACHINE LEARNING IN CASTING INDUSTRIES:

Machine Learning technologies are transforming the casting industry by providing data-driven insights and automation, leading to improved quality, cost savings, and overall operational efficiency. Applications of ML help foundries produce high-quality castings while remaining competitive in a global manufacturing landscape.

Some of key roles of ML for foundries are:

- Process Optimization: Machine learning algorithms can analyze historical process data to identify patterns and optimize various parameters such as temperature, pressure, pouring rates, and mold designs. Optimization leads to improved casting quality, reduced energy consumption, and decreased production costs.

- Simulation and Design Improvement: Machine learning can enhance casting simulation software by making it more accurate and efficient. It aids in virtual prototyping and design optimization, saving time and resources.

- Defect Prediction and Prevention: ML models trained on historical data can predict potential defects and casting irregularities by identifying patterns associated with defects. This enables early intervention to prevent defects, reduce scrap rates, and improve overall product quality.

- Root Cause Analysis: In case of defects or failures, ML can help identify the root causes by analyzing historical and real-time data, leading to targeted improvements

- Quality Control and Defect Detection: Machine learning models can analyse images and sensor data from casting processes to detect defects like cracks, porosity, inclusions, and surface irregularities in real-time. Early defect detection allows for immediate corrective actions, reducing the production of faulty castings and minimizing scrap.

IMPLEMENTATION OF MACHINE LEARNING IN CASTING SIMULATION SOFTWARE:

Machine learning (ML) plays a crucial role in casting simulation software, enhancing its capabilities and improving the accuracy of predictions and simulations. The integration of ML techniques with casting simulation software adds a layer of intelligence and predictive capabilities, allowing engineers and manufacturers to optimize casting processes and improve the quality of cast components.

Some of Benefits of implementing Machine learning in Casting simulation software:

- Improved Accuracy: Machine learning algorithms can analyze vast amounts of historical casting data, including process variables, material properties, and outcomes. This data-driven approach enhances the accuracy of predictions, allowing for more reliable simulation results.

- Enhanced Predictive Modeling: ML can improve predictive models used in casting simulations. For example, it can better predict solidification patterns, shrinkage, and defects by learning from past simulations and real-world data.

- Defect Detection and Prevention: ML algorithms can help detect potential defects in the casting process by analyzing data in real-time. This allows for immediate corrective actions and reduces the likelihood of producing defective castings.

- Faster Simulation Times: ML can accelerate simulation times by optimizing the simulation parameters and focusing computational resources on critical areas of the casting process, reducing the time and resources required for simulations.

- Optimized Process Parameters: Machine learning can identify optimal process parameters, such as pouring temperature, mold design, and gating systems, by analyzing historical data and their impact on casting quality.

- Decision Support: Machine learning can provide decision support tools for engineers and operators by offering insights and recommendations based on historical data and ongoing simulations.

- Continuous Learning and Improvement: Machine learning allows casting simulation software to continuously learn and adapt to new data, trends, and production conditions, ensuring that simulations remain relevant and accurate over time.

By analyzing above benefits simulation software’s existing in present market are exploring this technology for better defect prediction and Advance Defect Predication Tool (ADPT) in ADSTEFAN Casting simulation software is one such tool developed by Hitachi ICS Japan which will help users to analyze defects in less time and higher prediction accuracy using Machine Learning. This tool uses master data or database created by users to predict defects in target project by Machine Learning.

Defect prediction can be used for target projects of same cast alloy with different casting design and process parameters. Defect database for defects like flow marks, cold shuts, misrun, gas porosity, inclusions etc., can be created.

Steps in ADPT:

Below are steps for Advance Defect Prediction Tool (ADPT)

- Register the corresponding actual defect information and use it as Master data.

- Create a defect prediction database by machine learning one or more Master data.

- By inputting the analysis result of a new normal project into this database, we will provide a system for making the next prediction.

- Since the output by ADPT is based on the actual defect information registered in the Master data, the output result is not an indirect index but a more direct and specific defect occurrence rate.

Benefits of ADPT:

- More accurate defect prediction can be done compared to conventional method as

- defect prediction is done by using past shop floor results data.

- Past learning data is stored in database that can be utilized for future projects.

- Wider range of defects can be predicted compared to conventional method.

- More range of defects can be predicted within less time.

CASE STUDY FOR DEFECT PREDICTION USING MACHINE LEARNING:

We will demonstrate a case study to understand defect prediction by Machine Learning. To implement products should be of the same material grade and casting process.

Machine Learning uses data of defect type and defect intensity for prediction in target project.

Training data preparation:

For training data preparation, we have identified the casting part as shown in below figure. The process is Investment Casting and material is CF8M. We are going to train simulation software on shrinkage defect prediction.

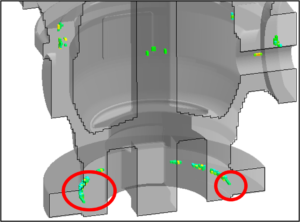

For training data, we have considered 3 iterations with change in gating design and same pouring is done on shopfloor and Shrinkage locations are identified as per for iteration 1. Defect intensity is observed 0.8 respectively as per locations displayed in below fig .

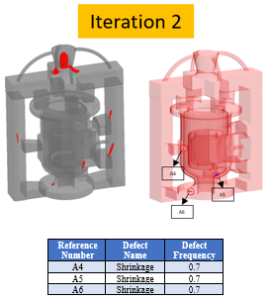

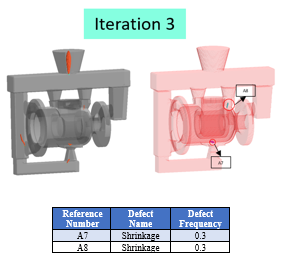

For the second and third iteration, the Methoding system is redesigned to overcome shrinkage porosity defect as per fig 1.4 & fig 1.5. As per shopfloor casting observation, defect location and intensity is identified and considered same in master defect database set.

The above 3 iteration details are collected from the shopfloor and master defect database is created in ADSTEFAN simulation software and this data can be refereed to any project with Investment Casting with material CF8M.

Implementation of Trained data for new project:

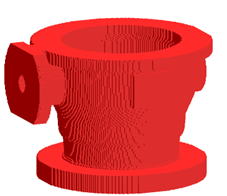

Now with created set database for defects – shrinkage defect in ADPT, we will implement in Project B to determine probability and locations of defect.

We have identified Project B as per below fig . The process is Investment Casting with material CF8M.

We have observed the probability of Shrinkage defect in Project B . Below figure are results for Defect prediction using Machine learning tool – ADPT for defects – Shrinkage porosity defect.

CONCLUSION:

Implementing machine learning in casting simulation software presents a transformative opportunity for the foundry and manufacturing industries to enhance casting quality and overall operational efficiency. This technology leverages the power of data-driven insights, automation, and predictive modeling to address longstanding challenges in the casting process.

As ML techniques continue to evolve, they have the potential to revolutionize how casting processes are designed, monitored, and optimized.

Casting simulation software are adapting these new technologies such as machine learning in their tool in order to achieve more accurate prediction rate of defects and thus helping foundrymen to take necessary actions to produce good sound castings in lesser lead time.

ACKNOWLEDGMENT:

We thank Hitachi ICS – ADSTEFAN team for their continuous support.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings