Cold Shut Casting Defect in Sand Casting

Cold shut casting defect refers to a type of casting defect that occurs when molten metal does not properly fuse together during the casting process. When molten metal enters the mold from two gates, the streams will meet at a junction. Low Temperatures can prevent fusion at the junction, causing the streams to solidify before fusion, creating a cold shut defect in casting.

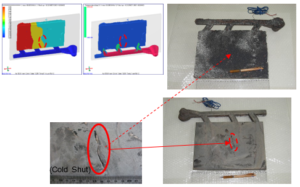

a. Cold shut casting defect in component

Cold shuts can be caused by a lack of fluidity in the metal. Fluidity is a very important consideration in metal casting. Fluidity is influenced by a range of factors, most notably the pouring temperature. The temperature must be sufficiently high to avoid casting defects but not excessive. The Gating system also plays a crucial role in preventing casting defects such as misruns and cold shuts. A good gating system ensures that the metal is kept in a liquid state for enough time to fill the extremities of the mold cavity

Root Causes of Cold Shut Defects:

Several factors contribute to cold shut defects in sand casting:

- Low Pouring Temperature: Insufficient pouring temperature leads to improper fusion of molten metal streams, leads to cold shut defect in component.

- Slow pouring: Slow pouring of molten metal leads to more temperature drop during filling and leads to cold shut defect in component.

- Poor Gating Design: Improper gating and riser design can result in more temperature drop during metal flow, increasing the likelihood of cold shut formation.

- Alloy Composition: Certain alloys are more prone to cold shut defects due to metallurgical properties, including high viscosity and low fluidity.

- Casting Geometry: Complex geometries and thin sections are high risk of cold shuts, due to non -uniform metal flow and solidification.

Overcome Cold shut defects:

- Pouring temperature: The Pouring temperature must be sufficiently high to avoid casting defects but not excessive.

- Pouring Rate: Proper pouring rate needed to be followed to overcome temperature drop during filling of molten metal in cavity.

- Gating Design: Proper gating system to be designed to ensures that the metal is kept in a liquid state for enough time to fill the extremities of the mold cavity

- Alloy Composition: Selection of alloy compositions and improve in less viscosity and more fluidity.

Through using casting simulation tools such as ADSTEFAN – Hitachi ICS – Japan based software, Design engineer can access flow conditions of molten metal in cavity whether for given conditions and gating design any temperature drop is detected in cavity. This early detection helps design team to re modify gating design and reiterate simulations and best conditions and gating design with no casting defects can be selected and followed by pattern development and shop floor trails.

Below are images comparison between casting simulation ADSTEFAN Simulation results with actual cold shut casting defect. As observed, there is a temperature drop at highlighted region where molten metal is joining in casting from multiple in gates. Due to temperature drop, cold shut defect is formed in casting. In ADSTEFAN, one can measure temperatures in any place at any point of time during mold filling. Thus, gives gating designer a complete idea of temperature variation of molten metal during pouring and can predict cold shut defect in casting well before pattern is even made. Thus, it saves energy, production cost and development lead time.

b.Defect mapping for Cold Shut defect between ADSTEFAN results and Shop floor trails

By using casting simulation software ADSTEFAN and Aganita expertise can predict exact location of Cold shuts casting defect and necessary optimization of gating system and pouring temperature. More iterations for optimizing of gating system can be done within a short period compared to conventional method of trial and error in shop floor thus reducing time, labor cost and cost for trails.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings