Casting Yield improvement using Gravity Die Casting simulation of an Alloy Wheel

Reducing /controlling casting defects and Achieving casting yield improvement are critical objectives for Indian foundries striving for competitiveness. These goals not only impact operational costs but also influence product quality and customer satisfaction. We explain here in this case study, methodologies for casting rejection reduction / elimination and casting yield enhancement. We explain how casting simulation software helps Indian foundries to enhance casting yield increase and effectively understand Casting defects and remedies. Gravity die casting of an alloy wheel is explained in this case study,

Casting Yield Enhancement and Improvement

The Casting yield is defined as the weight of the casting divided by the weight of the total amount of metal poured. Casting yield improvement is achieved by following:

- Gating Optimization: Casting methoding, encompassing the design of gating systems and risers, plays a vital role in managing casting defects such as shrinkage porosity, blow holes, air entrapment, sand inclusion, crack, warpage, cold shut, misrun etc. Employing advanced casting methods simulation and metal melting simulation tools enables accurate prediction of potential casting defects prior to production, thereby significantly enhancing overall process efficiency. Usage of such casting defect prediction methods deploying casting simulation software will help in gating optimisation.

- Process Optimization: Process parameters such as Pouring temperature, pouring time, pouring rate, Die temperature, Cooling lines placement play a vital role in managing casting defects such as shrinkage porosity, blowholes, inclusions, crack, cold shut etc., By using advanced casting methods simulation tools enables precise optimization of above mentioned process parameters and accurate prediction of potential casting defects prior to production, thereby significantly enhancing overall process efficiency.

- Using Casting simulation technology: Integrating casting methods simulation, These innovations empower foundries to simulate casting processes accurately, gating optimization designs, and to enable shrinkage porosity prediction, (or casting porosity prediction), air entrapment prediction, casting crack prediction, and other defects before commencing production. By minimizing trial-and-error, these advancements streamline operations, boost efficiency, and elevate the overall quality of castings produced.

We use casting simulation software ADSTEFAN as gravity die casting simulation software in this case study. ADSTEFAN has also been used for high pressure die casting simulation, analyse thermal balancing die casting, It has also been used as casting mold flow simulation tool and as a sand casting simulation software. In this case study we focus on usage of gravity die casting simulation software for prediction of casting defects and remedies in casting of an alloy wheel.

Case studies in area of Yield improvement:

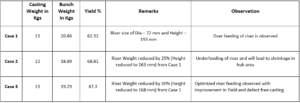

We have considered an Alloy wheel casting of A356 material, as shown in figure 1 which is produced through gravity die casting (GDC) process. Weight of Alloy wheel is 13 Kgs and along with initial gating design, Bunch weight of casting is 20.86 Kgs with Yield 62.32 %.

Figure 1: Alloy wheel for 4-wheeler Passenger Vehicle

In Case 2, 25% of center hub riser is reduced and thus total bunch weight obtained is 18.89 Kgs with yield 68.81% and in Case 3, 20% of center hub riser is reduced and bunch weight of Case 3 is 19.29 Kgs with yield 67.3 %. All the three cases were simulated using ADSTEFAN casting simulation software.

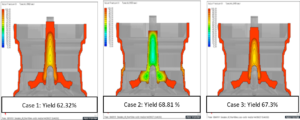

Below are results of solidification analysis for simulations performed. As observed, there isolation in solidification for Case 2.This indicates the length of riser used is far less than required factor of safety thus leads to shrinkage porosity defect at hub area which is a very critical location. Whereas in Case 3 with 20 % of reduction of riser, we are still achieving directional solidification and the factor of safety is on higher side compared to Case 2

Figure 2: Solidification behavior of Alloy wheel component with 3 different Methoding designs using ADSTEFAN casting simulation.

From results shown in figure 2, considering factor of safety Case 3 is best Methoding design and yield improvement for Alloy wheel component is optimized from 62.32% to 67.3 % saving raw material utilization and energy cost.

Conclusion:

Using Casting simulation software, foundries can perform Gating optimization and parameter optimization virtually, identifying potential casting defect and remedies before physical production begins. In this case study yield was increased by about 5% without compromising on the casting quality and without any additional investment in process controls.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings