Benefits of effective utilization and benefits using casting simulation software for Indian Casting manufacturer

India has a robust casting industry with a wide range of foundries catering to various sectors such as automotive, aerospace, defense, railways, and general engineering. The casting industry in India encompasses both ferrous and non-ferrous metals, including cast iron, steel, aluminum, and copper-based alloys. Indian foundries produce a diverse array of cast components, including engine blocks, cylinder heads, transmission housings, brake components, pump housings, and more.

Indian casting manufacturers have established a strong presence in international markets, supplying cast components to leading OEMs and tier-1 suppliers across industries. India is 2nd largest producer of casting of approx. 14.16 Million MT per annum in 2022-23 (up from previous year 13.78%), India continues to be the second largest producer of castings in the world with workforce of 2.0 Million (Direct 0.5 Million & Indirect 1.5 Million) and revenue of USD 20.0 Billion with export approx. USD 3.94 billion.

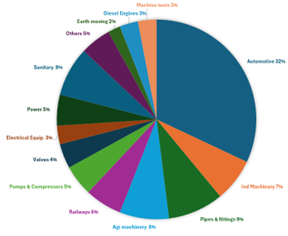

Fig 1. % casting parts produced with respect to Sector wise

CHALLENGES FACED BY INDIAN FOUNDRIES:

Indian foundries encounter several challenges in their pursuit of casting excellence. One prominent challenge is the technological gap. This technological obsolescence not only affects productivity but also hampers their ability to produce high-quality castings consistently.

Raw material price fluctuation has become great burden for foundries across globe. With these fluctuating trends, it becomes more difficult for Casting manufacturers and their suppliers as one can’t be able to forecast price of produced casting and foundries are taking big gamble for it. For many castings, material represents 50% or more of the cost. This creates financial pressure for foundry and their supplier too.

Indian foundries need to adapt for new technologies available in market that can help foundries to cut raw material utilization cost and optimize process parameters for good quality castings.

CASTING SIMULATION SOFTWARE TECHNOLOGY:

Casting simulation software is a powerful tool utilized by foundries to digitally replicate and analyze the casting process before actual production begins. It enables foundries to simulate the flow of molten metal into molds, solidification, cooling, and the formation of the final casting. By inputting various parameters such as material properties, mold geometry, and process conditions, casting simulation software predicts potential defects and optimizes the casting design and process parameters to achieve desired outcomes.

Casting simulation software facilitates virtual experimentation, allowing foundries to explore different scenarios, identify potential issues, and optimize the casting process for improved quality and efficiency. Moreover, casting simulation software aids in defect prediction and prevention by simulating the occurrence of defects such as shrinkage, porosity, and hot spots, enabling foundries to implement preventive measures and minimize scrap and rework.

Overall, casting simulation software empowers foundries to enhance their casting processes, reduce costs, improve product quality, and streamline operations, ultimately contributing to increased competitiveness and success in the marketplace.

The major benefits of using a casting simulation are:

- Reduction in Product Development Time

- Validation of Gating/Methoding design

- Reduction of rejection rates by improving casting quality

- Continuous improvements such as Yield Optimization

- Process parameter optimization.

Inputs of Casting simulation software:

- The geometry of the mold cavity (3D model of the casting, feeders, and gating channels).

- Boundary conditions (i.e. the metal Mold heat transfer coefficient, for normal Mold as well as feed aids including chills, insulation and exothermic materials).

- Thermo-physical properties (density, specific heat, and thermal conductivity of the cast metal as well as the mold material, as a function of temperature).

- Process parameters (such as pouring rate, time and temperature).

Outputs of Casting simulation software

- Animated visualization of mold filling, casting solidification, and further cooling to room temperature.

- Mold filling simulation helps in predicting the total filling time, mold/die erosion (leading to sand inclusions), incomplete filling (cold shuts and misruns), and air entrapment.

- Casting solidification simulation shows the temperatures gradients and cooling rates inside the casting, which are used for predicting the location of shrinkage porosity based on Niyama and other criteria.

- Further cooling to room temperature can also be simulated, which is useful for predicting microstructure, mechanical properties, residual stresses, and distortion.

Common Challenges faced during Simulation. Some of common challenges faced by user during simulation:

- Lack of data/3D Models

- No knowledge about process

- No clear data provided by shopfloor team like Optimum pouring temperature, Die temperature, Pouring rate/Time.

- Assumptions of input data

- Wrong setup considerations

- Improper results interpretation

EFFECTIVE UTILIZATION OF SIMULATION SOFTWARE:

Through Casting simulation software tool, foundries can optimize casting designs and mold geometries virtually, identifying potential defects before physical production begins. To achieve this foundry, need to effectively utilize simulation software tool and reap benefits such as reduction in product development time, optimal utilization of resources etc., In below we are listed some of points from our experience how to effectively utilize casting simulation software.

- Involving CFT team for simulation activities: For new RFQ projects, by conducting CFT meeting and brainstorming with all members on product gating design and preparing various Methoding concepts. These concepts can be modelled and proceed for simulation and results can be compared for all Methoding concepts and best design with better yield and less/no defects can be identified and same can be proceed with shop floor trails. By involving CFT for simulation will help to produce new ideas and concepts and thus leads to cut short product development time.

- No assumptions of input data: Simulation software results directly depend on simulation inputs provided. No assumptions in input data should be encouraged. Before setting of simulation, engineer must circulate process parameters sheet which will have all inputs that they are going to consider for simulation. If any improvement/changes can be suggested before proceeding for simulation activity

- Knowledge about process: Simulation engineer should have proper training and experience in process as inputs to be provided in simulation should match with actual shopfloor feasible conditions.

- Proper training is required for simulation engineer on tool utilization for simulation setup, execution, and results interpretation. If any deviations in simulation setup results in deviation in defect prediction. Detailed SOP to be prepared and simulation engineer need to be trained for simulation setup, execution, and results interpretation.

CONCLUSION:

In conclusion, the effective utilization of casting simulation software offers numerous benefits for Indian casting manufacturers, empowering them to enhance their operations and competitiveness in the global marketplace. By effective utilization of simulation software, Indian foundries can optimize casting designs, refine process parameters, and predict and prevent defects, ultimately improving casting quality while minimizing production costs and material wastage, ensuring that Indian foundries can meet the demands of both domestic and international markets.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings