Air entrapment prediction using ADSTEFAN gravity die casting simulation software

Gravity Die Casting is a widely used process for producing high-quality metal components with excellent dimensional accuracy and surface finish. However, like any manufacturing process, it is susceptible to casting defect, and one of the most common issues encountered is gas porosity.

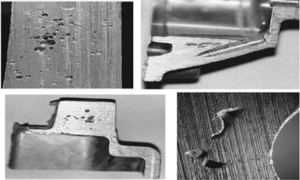

Gas porosity casting defect in gravity die casting can significantly affect the quality and integrity of cast components. They occur when air becomes trapped within the solidified metal, leading to internal voids or pores. These voids may range in size from tiny pores to larger cavities and can adversely affect the mechanical properties, surface finish, and overall quality of the casting Understanding the causes, effects, and prevention methods for gas porosity is crucial for optimizing casting processes.

A.Gas Porosity Defect in casting

- The gating and venting design plays a crucial role in preventing gas porosity defects. Inadequate venting or improper vent placement can prevent trapped gases from escaping, leading to porosity issues.

- The temperature of the molten metal is critical in controlling the formation of gas porosity. If the metal temperature is too high, it can increase gas solubility, leading to more gas being absorbed into the metal. On the other hand, if the temperature is too low, gases may not be able to escape effectively, resulting in trapped bubbles.

- Proper mold design, including adequate venting and gating systems, is essential for minimizing gas porosity defects. Venting channels should be strategically placed to allow trapped gases to escape during filling. Maintaining consistent pouring conditions, such as controlled metal flow rate and pouring temperature, can help minimize turbulence and gas entrapment during filling.

Gas porosity defects pose significant challenges in gravity die casting, affecting both the quality and performance of cast components. By understanding the underlying causes of gas porosity and implementing effective prevention strategies, manufacturers can minimize defects and produce high-quality castings consistently.

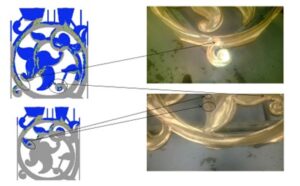

Through air entrapment simulation tools such as ADSTEFAN GDC simulation software, Design engineer can perform air entrapment prediction and understand air evacuation pattern during filling of molten metal inside mold cavity and check for air pocket isolation is forming during filling of metal inside mold cavity through casting porosity prediction software – ADSTEFAN. This early detection helps design team to remodify gating design and reiterate simulations by modifying gating design and providing vents are air trapped location.

b. Defect mapping for Blow holes defect between ADSTEFAN results and Shop floor trails

Above figure(b) demonstrates defect mapping of blow holes defect for GDC process with ADSTEFAN air entrapment simulation tools. We have simulated flow pattern and blue color in image represents air inside cavity during filling and transparent color represents already filled molten metal at these areas. The root cause of defect is identified as air pocket isolations during filling which is highlighted are observed in casting in ADSTEFAN gravity die casting simulation. Due to this air pocket isolation is observed in cavity which leads air gets entrapped between the molten metal and thus forms as Gas porosity in casting and same phenomenon is observed in shop floor trails.

Preventive action taken on component by gating optimization and provide air vents in location where air pocket isolated and thus blow holes defect is controlled. This gating optimization is carried out in ADSTEFAN casting simulation software and best gating design, and vent locations are considered in shop floor trails thus leading to elimination of blow holes defect in shopfloor. By performing corrective actions using ADSTEFAN casting simulation software, we can reduce shop floor trails, production, and development time of component.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings