Understanding and Preventing Slag Inclusion Casting Defects in Sand Casting

Slag inclusion defect is one of common casting defects in sand casting process particularly when casting ferrous metals. Slag inclusion defects in casting are mainly formed due to improper molten metal flow inside mold cavity.

More chances of slag inclusion occur due to low temperatures and more contact time with oxygen that is present in environment and mold. More time metal is exposed to oxygen, more slag is formed by converting in molten metal into oxide form.

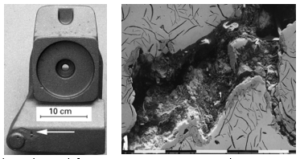

Fig A. Slag inclusion defect in casting. Courtesy – Foundry Lexicon

Factors effecting slag inclusion casting defect in sand casting are high impurity levels in materials, Slow pouring time of molten metal at low pouring temperatures and more turbulence also leads to slag inclusion defect in casting.

Prevention:

- Use High-Quality Raw Materials: Start with clean, high-quality sand and metal alloys to minimize impurities and reduce the likelihood of slag formation.

- Proper Fluxing: Select appropriate fluxes and ensure proper application to effectively remove impurities and minimize slag formation during melting.

- Controlled Pouring: Pour the molten metal into the mold in a controlled manner to minimize turbulence and prevent slag entrapment. Proper gating and riser design can help facilitate smooth metal flow.

- Skimming: Regularly skim the surface of the molten metal to remove any slag or other impurities before pouring.

- Quality Control: Implement rigorous quality control measures, including visual inspection, non-destructive testing, and metallographic analysis, to detect and address slag inclusion defects early in the production process.

- Using Casting defects and remedies tool such as Casting simulation software: By using sand casting simulation software such as ADSTEFAN user can able to predict probability of defect and take necessary actions either in optimizing gating design or process parameters.

In order to overcome slag inclusion defect, proper gating design with slag traps to be provided along with filling of cavity in laminar way and also adequate pouring temperature and pouring time to be maintained so that reaction with oxygen in air and cavity will be reduced

Through using casting simulation tools such as ADSTEFAN – Hitachi ICS – Japan based software, Design engineer can access flow conditions of molten metal in cavity whether for given conditions and gating design, predict casting defects and detect any turbulence in cavity. This early detection helps design team to remodify gating design and reiterate simulations and best conditions and gating design can be selected and followed by pattern development and shop floor trails.

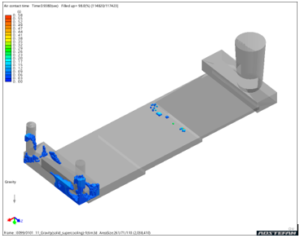

Fig B. Air contact results in ADSTEFAN simulation software

Above figure(b) demonstrates air contact time of molten metal inside cavity for sand casting process with ADSTEFAN simulation software results. Higher contact time with molten metal and air, higher chances of slag inclusion in casting. Design engineer can also validate temperature distribution and filling velocity of molten metal during filling of mold cavity.

Preventive action taken on component by modifying gating design and process parameter optimization to reduce more contact time with air, high filling velocities and thus slag inclusion defect is controlled. This optimization is carried out in ADSTEFAN software and best gating design, and process parameters are considered in shop floor trails thus leading to elimination of slag inclusion casting defect in shopfloor. By performing corrective actions using ADSTEFAN simulation software , we are able to reduce shop floor trails, production, and development time of component.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings