Study on effect of tilt time on quality of casting parts in Tilt GDC process using ADSTEFAN

Abstract:

The Tilt Gravity Die Casting (GDC) process is a widely used manufacturing method for producing high-quality metallic components, with tilt time being a critical parameter influencing casting quality. This study investigates the effect of tilt time on the quality of castings by combining experimental analysis and advanced simulation using ADSTEFAN software.

The research highlights improper tilt times consideration negatively impact flow dynamics, leading to defects such as shrinkage porosity, Gas porosity and turbulence-induced porosity. By optimizing tilt time, manufacturers can achieve sound castings. This study demonstrates the effectiveness of using ADSTEFAN as a predictive tool for process optimization, offering valuable insights to improve casting quality in the Tilt GDC process.

Keywords: Tilt Gravity Die Casting (GDC), ADSTEFAN simulation, Porosity, Shrinkage defects, Process optimization, Aluminum alloys, Casting simulation, Defect minimization, Casting quality

Introduction

Gravity Die Casting (GDC) is a cornerstone of modern manufacturing, enabling the production of robust, high-precision components. In recent years, the tilt GDC process has emerged as a game-changer, allowing manufacturers to control metal flow dynamics and reduce defects through the strategic tilting of molds during pouring. But how does tilt time seemingly subtle parameter impact the quality of casting parts?

At the intersection of advanced simulation, our recent study explored this question using ADSTEFAN, a powerful simulation tool. The findings not only shed light on the science of casting but also provide actionable insights for manufacturers striving to enhance their processes.

Why Tilt speed Matters

Tilt time in the GDC process has major impact on molten metal flows into the mold. If the mold tilts too quickly, turbulence increases, leading to defects like air entrapment and porosity. On the other hand, overly slow tilting risks premature solidification, causing cold shuts and uneven filling. Striking the right balance is essential to ensure a uniform, defect-free casting.

Here’s an overview of its significance and how it affects various aspects of casting quality:

Flow Dynamics

- Short Tilt Time: When the mold tilts too quickly, molten metal flows turbulently, increasing the risk of air entrapment, surface defects, and incomplete mold filling. This turbulence can also lead to cold shuts and uneven metal flow.

- Long Tilt Time: Excessively slow tilting may cause premature solidification at the gates or entry points of the mold. This results in incomplete filling and defects like shrinkage.

- Optimal Tilt Time: A balanced tilt time ensures smooth and controlled flow, reducing turbulence and providing uniform mold filling.

Defect Formation

- Gas Porosity: Rapid tilt times can lead to high turbulence, trapping air and forming porosity in the castings. In contrast, intermediate tilt times allow proper venting of air, minimizing porosity.

- Shrinkage: Longer tilt times can lead to uneven solidification patterns, resulting in shrinkage defects. Controlled tilting ensures uniform cooling, reducing this issue.

Microstructure

- Grain Size and Uniformity: The rate at which molten metal fills the mold and solidifies impacts the microstructure. Short tilt times often lead to coarse grains due to rapid solidification, while excessively long tilt times result in uneven grain structures. Optimal tilt times promote fine, uniform grain structures, enhancing the mechanical properties of the casting.

Mechanical Properties

- Strength and Ductility: Castings with minimal defects and uniform microstructure exhibit superior mechanical properties. Optimum tilt times maximize tensile strength and elongation by ensuring defect-free, high-quality castings.

Now we understand the effect of tilt speed time on quality of casting parts we have done experimentation on running multiple iterations with change in tilt time using ADSTEFAN casting simulation software.

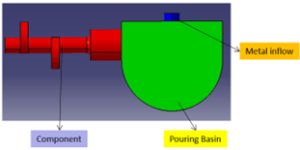

Fig 1: Model considered for Case study

Above model is considered to study effect of tilt time. Material is LM 6 and bunch weight of 0.3 kgs. In simulation we have considered pouring cup and total cup filling time is considered as 1.5 seconds and Tilt time as shown in below table. Case 1 considered initial slow tilting later steady tilt condition and Case 4 – Faster tilting condition . Die is considered CI with die temperature of 250°c.

| Rotation Angle (deg) | ||||

| Time (s) | Case 1 | Case 2 | Case 3 | Case 4 |

| 0 | 0 | 0 | 0 | 0 |

| 1.5 | 0 | 0 | 0 | 0 |

| 2.5 | 10 | 15 | 25 | 20 |

| 3.5 | 20 | 30 | 50 | 40 |

| 4.5 | 30 | 45 | 75 | 60 |

| 5.5 | 40 | 60 | 85 | 80 |

| 6 | 90 | 90 | 90 | 90 |

Table 1: Rotation Angle(deg) consideration for Different cases

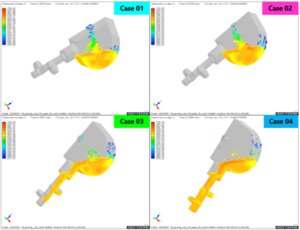

Below images represent filling of molten metal for all 4 cases. Observed early filling of molten metal in casting in Case 4 as it is a fast pouring and same phenomenon is observed in ADSTEFAN casting simulation results. At end of filling observed least temperature in Case 1 of 622°c compared to Case 4 of 628°c.

Fig 2: Comparison of filling temperature results in all 4 cases

Regarding filling velocity results observed highest in Case 4 – 1.26 m/s and lowest in Case 1 – 1.12 m/s which indicates that more turbulence filling is observed in Case 4.

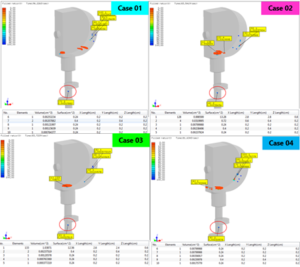

Fig 3: Comparison of shrinkage porosity results in all 4 cases.

In shrinkage porosity prediction observed shrinkage in all cases at highlighted locations as shown in fig 3. This is due to inefficient feeding of riser. Observed isolations during solidification at these regions are main root cause. When compared with shrinkage porosity volume as shown in below table 2 observed less shrinkage volume is Case 1 compared to all other cases.

| S No | Shrinkage Porosity Volume |

| Case 1 | 0.0020788 |

| Case 2 | 0.0023849 |

| Case 3 | 0.0023751 |

| Case 4 | 0.0023097 |

Table 2: Shrinkage porosity volume comparison for all 4 cases.

By understanding all 4 cases results, we can conclude that Case 1 where observed initial slow tilting and later steady tilt observed best results in are of Filling temperature distribution, air evacuation and laminar flow of molten metal and volume of shrinkage porosity is less compared to other cases.

Conclusion

This study highlights the critical role of tilt time in the tilt GDC process. By employing ADSTEFAN simulation software, it was possible to model and optimize the process parameters effectively. The results demonstrate that Case 1 offers the best outcomes in terms of minimizing defects. These findings provide valuable guidelines for manufacturers aiming to improve the quality and reliability of their castings.

References

- ADSTEFAN Simulation Software Documentation.

- Campbell, J. (2015). Complete Casting Handbook. Elsevier.

- Ravi, B. (2011). Metal Casting: Computer-Aided Design and Analysis. PHI Learning.

- Zhao, Z., & Li, Y. (2020). “Optimization of Casting Parameters in Gravity Die Casting.” Journal of Manufacturing Processes, 56, 25-32.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings