Shrinkage Porosity Defect in LPDC Causes, Solutions, and the Role of ADSTEFAN Casting Simulation Software

Introduction:

Low Pressure Die Casting (LPDC) is a popular manufacturing method for producing high-quality metal parts, especially in industries like automotive and aerospace. However, like any casting process, LPDC is prone to defects, and one of the most common and critical ones is shrinkage porosity. This defect can significantly impact the strength, appearance, and functionality of cast components, leading to costly rework or scrap. In this blog, we’ll explore what shrinkage porosity is, its causes, how to overcome it, and how ADSTEFAN casting simulation software can help predict and prevent this issue.

What is Shrinkage Porosity?

Shrinkage porosity refers to the voids or cavities that form inside a casting as it solidifies and cools. These voids are a result of the metal shrinking during the transition from liquid to solid. As the molten metal cools, it contracts, and if the metal doesn’t have enough liquid supply to fill the gap, shrinkage porosity occurs.

In LPDC, this defect is particularly concerning because it can weaken the structural integrity of the casting and lead to premature failure. It’s essential to identify and address shrinkage porosity early in the design and manufacturing process.

Causes of Shrinkage Porosity in LPDC:

Understanding the causes of shrinkage porosity is key to preventing it. Here are the main factors that contribute to this defect:

- Inadequate Cooling Rate: In LPDC, if the cooling rate is uneven the metal may solidify prematurely in some regions of the mold, causing uneven solidification of metal which leads to shrinkage porosity defect in casting. This is especially common in larger or more complex castings where cooling is uneven.

- Mold Design Issues: The design of the mold plays a significant role in preventing shrinkage porosity. Thin sections, sharp corners, and abrupt transitions can cause uneven solidification and improper metal flow, leading to voids and porosities. Mold design should ensure consistent flow of metal and proper venting

- Improper thermal balancing: Improper thermal balancing of die leads to improper solidification pattern of casting which leads to shrinkage porosity defects in casting.

How to Overcome Shrinkage Porosity in LPDC:

Now that we understand the causes, let’s look at the strategies to prevent and mitigate shrinkage porosity in LPDC:

- Optimized Mold Design: Improving the mold design is one of the most effective ways to prevent shrinkage porosity. Considerations like avoiding sharp corners, using fillets to ensure smooth flow, and adding risers and chills in thick sections can help the metal solidify uniformly.

- Improve Cooling System: The cooling rate must be carefully controlled. Using a cooling system that allows uniform heat removal from the mold can help ensure the casting solidifies evenly. Additionally, introducing controlled cooling or using chills at strategic points of the mold can help prevent unwanted porosity.

- Optimizing Gating / Process Parameters: Well-designed gating systems promote uniform metal flow and minimize turbulence and optimized process parameters such as P Vs T curve and considering sufficient holding pressure to overcome shrinkage porosity defects in casting.

Using ADSTEFAN Casting Simulation Software to Predict Shrinkage Porosity:

One of the most effective ways to address shrinkage porosity before production is to use casting simulation software. ADSTEFAN is a powerful tool for casting simulation that can help in shrinkage porosity prediction by LPDC simulation.

How ADSTEFAN Helps:

- Mold Filling Prediction: ADSTEFAN simulates the filling process of the molten metal, identifying areas where the mold unfilling defects can happen.

- Thermal Analysis: ADSTEFAN can predict the cooling rate and solidification pattern across the mold and predict shrinkage porosity defects

- Optimization of Gating design: ADSTEFAN allows engineers to optimize riser placement and cooling strategies to ensure that the molten metal feeds into areas that would result in shrinkage porosity.

- Porosity Prediction: Using advanced algorithms, ADSTEFAN predicts the formation of shrinkage porosity by simulating the solidification process and identifying areas where voids might form. This gives engineers the ability to adjust mold design, thermal balancing, and process parameters to reduce porosity.

- Design Iteration: ADSTEFAN enables designers to rapidly optimize different design iterations and casting parameters. This iterative process ensures that the final design minimizes shrinkage porosity and enhances casting quality.

Case study – Shrinkage prediction using Low pressure die casting simulation process in ADSTEFAN:

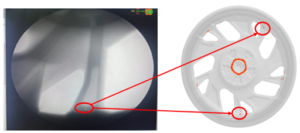

Above figure demonstrates defect mapping of shrinkage defect for LPDC process with ADSTEFAN die casting simulation software. We have simulated solidification pattern and found shrinkage porosity in smaller spoke due to ineffective cooling considerations in rim-spoke joint which is highlighted are observed in casting in ADSTEFAN Low pressure die casting simulation. Due to this shrinkage is observed in smaller spoke regions in casting and the same phenomenon is observed in shop floor trails.

Preventive action taken on component by gating optimization and process optimization by optimizing cooling lines switch on and switching off time inorder to get directional solidification. This process optimization is carried out in ADSTEFAN casting simulation software and optimum process parameters are considered in shop floor trails thus leading to elimination of shrinkage porosity defect. By utilizing ADSTEFAN casting simulation software, designer can take corrective actions and reduce shop floor trails, production, and development time of component.

Conclusion:

Shrinkage porosity is a common and critical defect in LPDC, but with the right strategies and tools, it can be effectively minimized. By focusing on optimizing mold design, controlling the cooling rate, manufacturers can significantly reduce the risk of shrinkage porosity.

ADSTEFAN casting simulation software plays a crucial role in predicting and preventing this defect. It allows engineers to simulate the casting process in a virtual environment, making it easier to identify potential issues like shrinkage porosity early on. By utilizing these advanced simulation tools, manufacturers can produce higher-quality castings while reducing the risk of costly defects.

By combining traditional methods with modern casting simulation software like ADSTEFAN, LPDC manufacturers can ensure the production of defect-free, high-quality castings that meet the stringent demands of today’s industries

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings