Sand Inclusion Casting Defect in Sand Casting

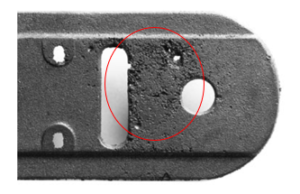

Sand inclusion casting defects, also known as sand inclusions or sand blow, are common casting defects in sand casting processes. It occurs when loose sand particles become trapped in molten metal and subsequently solidify within the casting. Sand inclusions casting defect can compromise the integrity and surface finish of the casting, leading to rejecting parts and increased production costs.

a.Sand inclusion defect in component

Causes of Sand Inclusion Casting Defects:

- High Pouring rate: High pouring rate will lead to more turbulence filling of molten metal in cavity which leads to infusion of sand particles into molten metal and causes sand inclusion defect in casting.

- Improper Gating and Riser Design: Incorrect gating and riser design can cause turbulence in the molten metal which leads to sand inclusion defect in casting.

- Mold Erosion: Over time, the surfaces of molds and cores can erode due to high filling velocities, releasing sand particles into the molten metal stream during casting.

- Sand Reclamation Issues: Reclaimed sand used in the moulding process may contain fines or other contaminants that can contribute to sand inclusion defects if not properly controlled.

Preventive Measures:

- Maintaining Proper pouring rate: By following proper pouring rate of molten metal reduces turbulence filling and controlling sand inclusion defect in casting.

- Optimize Gating and Riser Design: Designing efficient gating and riser systems helps to minimize turbulence and prevent the entrainment of sand particles in the molten metal. Proper gating design ensures a smooth, controlled flow of metal into the mold cavity.

- Maintain Mold Surfaces: Regular inspection and maintenance of mold surfaces help prevent erosion and the release of sand particles into the casting. Surface coatings or treatments may also be applied to extend mold life.

- Using sand casting simulation software: By using advanced sand-casting simulation software such as ADSTEFAN. Melt velocities in of mold, and turbulence can be simulated using casting simulation software. Engineers predict and modify the mold design and gating optimization to reduce the melt velocities and avoid turbulent filling to avoid casting defect such as sand inclusion casting defect in casting.

- Monitor Sand Quality: Implementing quality control measures for moulding sand, including proper sand testing and conditioning, helps to minimize the presence of fines and contaminants that can contribute to sand inclusion defects.

Through using casting simulation tools such as ADSTEFAN – Hitachi ICS – Japan based software, Design engineer can access flow conditions of molten metal in cavity whether for given conditions and gating design any turbulence is detected in cavity. This early detection helps design team to predict sand casting defects and gating design optimization casting defect and reiterate simulations and best conditions and gating design can be selected and followed by pattern development and shop floor trails.

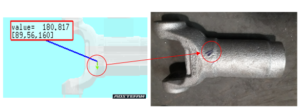

b.Defect mapping for sand inclusion defect between ADSTEFAN results and Shop floor trails

Above figure(b) demonstrates defect mapping of inclusion casting defect for sand casting process with ADSTEFAN simulation software results. Root cause of defect is identified as high velocities of over 180 cm/s in casting region in ADSTEFAN results. Due to this higher filling velocities turbulence is observed in cavity which leads to sand inclusion defect in casting and same phenomenon is observed in shop floor trails.

Preventive action taken on component by modifying gating design and process parameter optimization to reduce high filling velocities and thus sand inclusion defect is controlled. This optimization is carried out in casting simulation software -ADSTEFAN and best gating design, and process parameters are considered in shop floor trails thus leading to elimination of sand inclusion casting defect in shop floor. By performing corrective actions using ADSTEFAN simulation software , we are able to reduce shop floor trails, production, and development time of component.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings