Predicting Core Gas Casting Defect using Sand Casting simulation software

To provide intricate shape of castings, cores are used extensively in sand casting. Most of cores are of resin coated to provide sufficient strength to overcome high pressures inside cavity during filling and solidification. High volume of resins will have a negative effect as these binders tend to produce core gases when they come in contact with molten metal and causes casting defect. These gases affect the quality of casting. Sufficient venting must be provided in mold for these core gases to escape and obtain good sound casting.

Core Gas Casting defects and remedies:

- Core Venting: Inadequate venting of the cores can lead to the entrapment of gases such as air, steam, or volatile compounds during the casting process.

- Core Composition: The composition of the core material, including its moisture content and binder type, can influence gas evolution during casting.

- Core Design: Complex casting geometries or designs with intricate cores may present challenges in achieving proper gas venting design.

- Sand Quality: Variations in sand quality, such as grain size distribution and permeability, can affect gas permeation and evacuation.

Solutions for Core Gas Casting Defects:

- Optimize Core Design: Designing cores with adequate venting can facilitate the release of trapped gases during pouring and solidification process and overcome casting defects due to core gas.

- Improve Core Venting: Enhance venting by incorporating venting ribs, risers, or vents directly into the core design to allow for efficient gas evacuation.

- Control Core Moisture: Properly controlling the moisture content of core sand is crucial to minimize gas evolution during casting. Utilize moisture control techniques such as preheating or drying to achieve optimal conditions.

- Enhance Sand Quality: Selecting high-quality sand with appropriate grain size distribution and permeability can help promote effective gas permeation and evacuation.

- Process Optimization: Casting parameters such as pouring temperature, pouring rate, and solidification time needs to be optimized to control core gas casting defect.

Through using casting simulation tools such as ADSTEFAN, Design engineers can conduct air entrapment simulation, and core gas entrapment simulation. Further, engineer can provide gating design modifications and check for effectiveness of gas venting. Designer can detect possibilities of core gas defect location in casting before conducting physical trials in the plant.

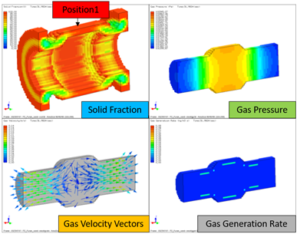

Figure (a) – Core gas results in ADSTEFAN simulation software

Above figure(a) demonstrates results of core gas casting defect for sand casting process in ADSTEFAN casting simulation software results. Solid fraction results display solidification pattern of material. Gas pressure results display gas pressure generated in sand core. Gas velocity vectors indicate core gas evacuation path and gas generation rate implies rate of core gas generated and its location. From the above results high core gas pressure are generated at center of core velocity vector at that moment are indicated inside casting. At the center of casting is still not 100% solidified so a high chance of generated core gas will penetrate casting at Position 1. Due to core gas entrapped at highlighted locations is observed in cavity which leads Core gas related casting defects in casting and same phenomenon is observed in shop floor trails.

Preventive action taken on component by modifying gating design provide proper venting and reducing resin % during core preparation thus core gas defect is controlled. This gating optimization and parameter optimization can be carried out in ADSTEFAN software and gating design and %resin in core is considered in shop floor trails thus leading to elimination of core gas casting defect in shopfloor. By performing corrective actions using ADSTEFAN simulation software, we are able to reduce shop floor trails, production, and development time of component.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings