Predicting Cold Shut Defects Using gravity die casting simulation software

Gravity die casting (GDC) is a popular metal casting process renowned for its capability to produce intricate and high-quality components with excellent surface finish and dimensional accuracy. However, like any manufacturing process, it is susceptible to casting defects, one of which is the cold shut defect. Utilizing GDC simulation software such as ADSTEFAN can help identify and mitigate these issues effectively.

Cold shuts, also known as cold laps or cold shuts, are discontinuities or surface defects that occur when molten metal fails to fuse together completely due to temperature drop, resulting in a visible seam or line on the casting surface. These defects can compromise the structural integrity and aesthetics of the cast component.

Cold shut defects pose challenges in gravity die casting, impacting both the quality and performance of cast components. By understanding the underlying causes of cold shuts and implementing effective prevention strategies, manufacturers can minimize defects and produce high-quality castings consistently.

Probable Causes of Cold Shut Defects in Gravity Die Casting

- Insufficient Molten metal Temperature: The metal temperature may not be maintained to the appropriate temperature, leading to incomplete filling of the mold.

- Poor Die Design: Inadequate gating and venting can restrict the flow of molten metal, causing it to cool before completely filling the mold.

- Low Pouring Speed: Slow pouring can result in the metal solidifying too quickly before complete filling of mold cavity, preventing proper fusion of metal streams.

- Inadequate Mold Preheating: If the mold is not preheated properly, leading to early solidification of metal even before completely filling of molten metal.

- Alloy Composition Issues: Variations in the alloy composition can affect fluidity and solidification characteristics, contributing to cold shuts.

Remedies for Cold Shut Defects

- Maintain optimum Pouring Temperature: Ensure the molten metal is poured to the optimal temperature for the specific alloy being used.

- Optimize Die Design: Review and modify the gating and venting system to ensure efficient metal flow and minimize turbulence.

- Increase Pouring Speed: Adjust the pouring technique to enhance the speed of metal entry into the mold, promoting better fusion.

- Proper Mold Preheating: Preheat the mold to a suitable temperature to minimize heat absorption from the molten metal and encourage proper filling.

- Control Alloy Composition: Regularly monitor and control the alloy composition to maintain consistent properties that promote better flow and fusion.

- Utilize Simulation Software: Implement GDC simulation software such as ADSTEFAN casting simulation software to predict potential cold shut issues and optimize the casting process and gating optimization before actual production.

By utilizing casting simulation tools like ADSTEFAN, design engineers can conduct casting defect prediction to assess the flow conditions of molten metal within the cavity. This allows for casting defect prediction under specific process parameters and gating designs, identifying any temperature drops in the cavity. Early detection enables the design team to Gating optimization and process parameters effectively. They can iterate simulations to determine optimal conditions, ensuring that potential casting defects are addressed before die development and shop floor trials. This proactive approach enhances the quality of castings and helps implement effective Casting defects and remedies

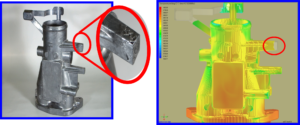

Defect mapping for Cold Shut defect between ADSTEFAN results and Shop floor trails for Gravity die casting process

Above are images comparing ADSTEFAN metal casting simulation results with actual castings. As observed, there is a temperature drop in the highlighted region where molten metal converges from multiple ingates, leading to the formation of a cold shut defect. Through casting mold flow simulation in ADSTEFAN, temperatures can be measured at any location and time during the mold filling process. This capability provides gating designers with a comprehensive understanding of temperature variations of molten metal during pouring, allowing for effective casting yield enhancement and accurate prediction of cold shut defects before the pattern is even created. As a result, this approach contributes to thermal balancing in die casting, ultimately saving energy, reducing production costs, and minimizing development lead time.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings