Machine Learning Implementation in ADSTEFAN Casting Simulation Software for Improved Product Quality

Introduction

The diecasting industry is vital to manufacturing, supplying essential components to sectors such as automotive, aerospace, and industrial machinery. To stay competitive in today’s fast-paced market, diecasting companies are leveraging technological advancements. This paper explores the transformative potential of integrating machine learning (ML) into diecasting processes, particularly through the use of casting simulation software.

The Advanced Defect Prediction Tool (ADPT), developed by Hitachi ICS Japan, is a cutting-edge solution designed to analyze defects with greater speed and accuracy using Machine Learning. Through detailed case studies and practical examples, this paper highlights the significant impact of ML integration in the diecasting industry. The successful application of ML algorithms, combined with casting simulation software, has led to notable advancements in efficiency and product quality

Machine Learning In Casting Simulation Software:

Machine learning (ML) is becoming a pivotal force in advancing the functionality of casting simulation software. By incorporating ML techniques, casting simulation tools gain enhanced predictive capabilities and smarter insights, enabling engineers and manufacturers to optimize casting processes and achieve higher-quality cast components.

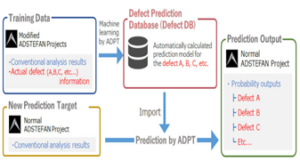

The Advanced Defect Prediction Tool (ADPT), developed by Hitachi ICS Japan, is a powerful solution designed to help users identify defects more quickly and accurately using Machine Learning. ADPT leverages a master database or user-created data to predict defects in a target project through Machine Learning techniques. Figure 1.1 illustrates the process flow of ADPT analysis.

Fig 1.1 – ADPT Analysis Process Flow

Defect prediction can be applied to target projects using the same cast alloy but with varying casting designs and process parameters. A defect database can be established to include casting defects such as flow marks, cold shuts, misruns, gas porosity, inclusions, shrinkage porosity, cracks, and heat sinks.

Benefits of ADPT:

- More accurate defect prediction can be done compared to conventional method as defect prediction is done by using past shop floor results data.

- Past learning data is stored in database that can be utilized for future projects.

- Wider range of defects can be predicted compared to conventional method.

- More range of defects can be predicted within less time.

Case Study For Defect Prediction Using Machine Learning:

In this paper we demonstrate a case study to understand defect prediction by Machine Learning. To implement ADPT, products should be of the same material grade and casting process. Machine Learning uses data of defect type and defect intensity for prediction in target project.

Training data preparation:

For training data preparation, we have identified the casting part as shown in fig 1.2 below. The process is High Pressure Die Casting and material is ADC 12. We are going to train simulation software on Shrinkage porosity defect prediction.

Fig 1.2 – Model considered for Training data

For training data, we have considered 3 iterations with change in gating design and same pouring is done on shop floor and shrinkage porosity locations are identified for all iterations. Master defect database is created in ADSTEFAN simulation software, and this data can be refereed to any project with High Pressure die casting process with material ADC 12.

Implementation of Trained data for new project:

Now with created set database for defects – shrinkage porosity defect in ADPT, we will implement in Project B to determine probability and locations of defect.

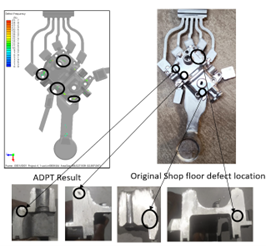

We have identified Project B as per fig 1.3. The Process is HPDC and Material is ADC 12.

Fig 1.3 – Model considered for implementation of trained data

We have observed that probability of Shrinkage porosity defect in Project B. Actual shop floor pouring is done based on model considered in Project B and we have observed Shrinkage porosity defect in locations identified as per ADPT results. Fig 1.4 shows comparison between shop floor defect results and ADPT results.

Fig 1.4 – Correlation between Shopfloor and ADPT

CONCLUSION:

The integration of machine learning with casting simulation software represents a transformative opportunity for the casting industry. This synergy enables proactive defect prevention, the optimization of process parameters, and the extraction of valuable insights that were once difficult to achieve. As machine learning techniques continue to advance, they are poised to revolutionize the way casting processes are designed, monitored, and refined.

Casting simulation software is increasingly incorporating these innovative technologies to enhance the accuracy of defect predictions. This evolution empowers foundry professionals to take timely corrective actions, ensuring the production of high-quality castings while reducing lead times.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings