How ADSTEFAN Casting Simulation Software Helps in Shrinkage Porosity Prediction

Introduction:

In casting, shrinkage porosity is one of the most common quality issues. It occurs when molten metal contracts during solidification and isn’t properly compensated by feeders or risers, leaving voids or isolations inside the casting. These defects can weaken the component, cause leaks, or result in failure during service.

Casting simulation software such as ADSTEFAN help to predict and prevent shrinkage porosity defect inside the casting before producing any physical part by this- saving time and number of trails. In this blog we will explore how ADSTEFAN casting simulation software helps to foundry engineers to reduce shrinkage porosity defects in casting.

Shrinkage porosity:

Shrinkage porosity happens when volume of reduction of molten metal as it solidifies. If there is no sufficient liquid metal feeding the last solidify region hotspot create in internal cavities or pores formed in casting area

For this shrinkage porosity eliminating engineers do trial and error, prototype casting and postproduction test to detect porosity. This process is expensive and time-consuming process.

ADSTEFAN Casting simulation software:

ADSTEFAN Casting simulation software provides physical based platform how actual shop floor process happen same we check in casting simulation software with different casting process like HPDC, GDC, TGDC and Sand Casting, with including results like fluid flow, Solidification analysis before actual die/pattern is developed.

Here’s how it helps shrinkage porosity prediction:

Solidification analysis– In simulation software models how molten metal flows and solidifies inside the mold. And highlights hotspot zone that solidifies last, these area chance to shrinkage porosity

Visualization of solidification:

- How the directional solidification happens inside the casting

- How gating and riser system impact feeding behaviour

- What changes can reduce the casting defect

Feeding system optimization:

- Observe feeding system optimization during solidification it’s in inner feeding or outer feeding we need to check

- Identify ineffective riser or feeder path

Design iteration without physical trails:

By getting any defect inside casting simulation helps to quick design changes like riser design, gating design, temperature variation and pouring time variation we need change again simulation for final good result.

Case study:

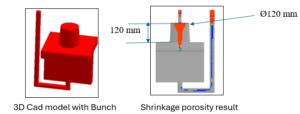

In this case study we have considered Sand Casting process with Material –Stainless steel, Casting Weight – 61.50 Kg , Bunch Weight – 77.38 kg and Yield – 79.47 %

Shrinkage results as shown in above figure indicated shrinkage inside casting section. Root cause of shrinkage in casting is improper consideration of riser.

Riser Optimization

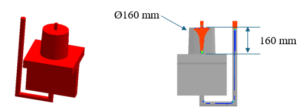

Above the result for optimized riser dimension Riser dia 120mm to 160mm and height 120mm to 160mm, and observed proper feeding of riser and the shrinkage porosity eliminated in casting area.

Benefits for foundry using ADSETFAN casting simulation

- Reduce Trial and error

- Reduce rejection rate

- Quality parts can produce easily

- Increase casting reliability and performance

Conclusion:

With the help of ADSETFAN casting simulation software designers can identify shrinkage porosity risks early and can optimize gating design for defect free castings and produce first time right, reduce waste, and deliver high-quality castings.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings