Heat Check mark prediction and understanding Thermal balancing die casting using ADSTEFAN High-Pressure Die Casting with Casting Simulation Software

Introduction:

In High-Pressure Die Casting (HPDC), achieving optimal die performance and high-quality castings relies on controlling several complex variables during the casting process. One of the most significant challenges in HPDC is managing thermal fatigue and the resulting heat checks that can shorten die life and reduce casting quality. Heat checks are surface cracks caused by the repeated thermal cycling of the die under high pressure and temperature conditions. These cracks can lead to die failure, casting defects, and increased downtime for maintenance.

To mitigate these challenges, hpdc simulation such as ADSTEFAN—a powerful tool for casting simulation—can be used to predict and manage heat check marks and ensure effective thermal balancing die casting processes. This article explores how ADSTEFAN hpdc simulation software can help with heat check prediction, and how it enables thermal balancing for improved die life and casting quality.

Understanding Heat Checks in High-Pressure Die Casting

In HPDC, molten metal is injected into a steel die at high speed and pressure, leading to rapid temperature changes as the metal solidifies. The die experiences extreme thermal cycles—heating up when exposed to molten metal and cooling down when the die opens to eject the casting. These thermal cycles put significant stress on the die material, which can cause cracks (heat checks) to form over time.

Key Causes of Heat Checks:

- Thermal Cycling: Rapid heating and cooling during each casting cycle.

- Uneven Cooling: Poorly designed or clogged cooling channels cause local overheating.

- Material Properties: Die materials with low thermal conductivity or insufficient thermal fatigue resistance are more susceptible to heat checks.

- Injection Parameters: Excessive injection speed, pressure, or temperature can cause thermal shock to the die.

These factors lead to thermal fatigue, which accumulates over many cycles and can manifest as heat check marks on the die surface. Heat checks typically appear at areas with high thermal gradients, where the cooling is inefficient or uneven.

ADSTEFAN metal casting simulation: A Tool for Heat Check Prediction

ADSTEFAN high pressure die casting simulation helps in optimizing the HPDC process, predict casting defect, and improve die performance. ADSTEFAN simulates the entire die casting process—from mold filling to solidification, allowing design engineers to assess thermal behavior, material flow, and cooling efficiency even before die manufacturing.

Thermal Balancing in HPDC: The Role of ADSTEFAN

Thermal balancing is the process of ensuring that heat is evenly distributed across the die during the casting cycle, preventing localized overheating and thermal gradients that can lead to heat checks. Proper thermal management is crucial for the die’s longevity and the quality of the castings.

How ADSTEFAN Facilitates Thermal Balancing:

- Optimized Cooling Channel Design: ADSTEFAN enables users to simulate the flow of coolant through the die and optimize the cooling channel layout. By ensuring uniform cooling, ADSTEFAN helps prevent the formation of hot spots, which are often the root cause of heat checks. The software can predict cooling efficiency and suggest modifications to improve heat dissipation.

- Simulation of Heat Transfer: ADSTEFAN simulates the heat transfer from the molten metal to the die and from the die to the cooling system. ADSTEFAN allows engineers to balance the thermal load across the entire die, reducing the risk of localized overheating and enhancing the overall thermal stability of the die.

- Incorporation of Conformal Cooling: ADSTEFAN supports the design and optimization of conformal cooling channels, which are designed to follow the contours of the die. Conformal cooling provides more efficient and uniform heat removal compared to traditional cooling channels, thereby improving thermal balance and reducing the risk of heat checks.

- Analysis of Die Material Properties: ADSTEFAN can assess how different die materials react to thermal loading. By simulating various material choices (such as H13, Dac Magic, or other heat-resistant alloys), the software can help engineers select materials with better resistance to thermal fatigue and heat checks.

- Process Optimization: ADSTEFAN metal casting simulation software can also simulate changes in casting parameters, such as injection speed, pressure, and temperature. By fine-tuning these parameters, ADSTEFAN helps ensure that the die experiences more controlled thermal cycling, reducing the risk of heat checks and other thermal-related defects.

Heat Check mark prediction using ADSTEFAN casting simulation software:

ADSTEFAN’s capabilities allow users to predict and analyze heat checks by simulating the thermal cycles the die undergoes during the casting process. The software provides detailed insights into:

- Temperature Distribution: ADSTEFAN die casting simulation allows engineers to visualize the temperature distribution across the die during each cycle, identifying areas where thermal stresses are likely to lead to heat checks.

- Cooling System Performance: ADSTEFAN allows for detailed analysis of the cooling system design, including the location and efficiency of cooling channels. It can help identify hot spots—areas that are prone to overheating—allowing for the optimization of cooling strategies to prevent excessive thermal cycling.

- Material Selection and Die Design: By modeling the properties of different die materials (e.g., tool steels like H13), ADSTEFAN helps engineers choose the most suitable material for specific thermal and mechanical conditions, reducing the likelihood of heat checks

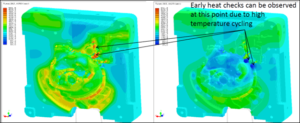

Die temperature before Spray Die temperature after Spray

The above figure represents die temperature before and after spray. Observed early heat checks can be observed at highlighted locations due to high temperature cycling. Thus, engineers can understand in detail about heat check marks prediction in die and also through thermal balancing and process parameter optimization and reduce formation of heat check marks.

Benefits of Using ADSTEFAN for Heat Check Prevention and Thermal Balancing

- Improved Die Life: By predicting heat check marks and optimizing cooling channels and thermal balance, ADSTEFAN helps reduce thermal fatigue and extends the life of the die, leading to fewer repairs and reduced downtime.

- Enhanced Casting Quality: Heat checks can cause surface defects in castings, leading to cosmetic issues and compromised part strength. By reducing the likelihood of heat checks, ADSTEFAN helps produce castings with better surface finishes and mechanical properties.

- Cost Savings: Effective thermal management reduces the frequency of die maintenance and replacement. Furthermore, simulation-driven process optimization and Gating optimization can lead to fewer casting defect, reducing waste and improving overall productivity.

- Faster Time-to-Market: By allowing engineers to simulate and optimize die performance and casting processes before die manufacturing, ADSTEFAN shortens the design and testing cycle. This leads to faster time-to-market for new products and improves overall process efficiency.

Conclusion

The combination of heat check prediction and thermal balancing is key to improving the longevity and performance of dies in the high-pressure die casting process. Using casting simulation software like ADSTEFAN, engineers can predict thermal behavior, optimize cooling systems, and select the most suitable materials to prevent heat checks and extend die life. The ability to simulate and optimize the casting process before shop floor trails in better casting quality, lower production costs, and faster time-to-market.

By leveraging the power of ADSTEFAN High-Pressure Die Casting Simulation Software, manufacturers can significantly enhance their HPDC processes, ultimately improving the reliability and profitability of their die casting operations.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings