Evaluation of Leak Risk Assessment at initial design level using ADSTEFAN casting simulation software

Introduction:

Leak testing for casting components is necessary requirement in ensuring the reliability, safety, and performance of the final product. Castings are often used in critical applications where even the smallest leaks can lead to significant consequences, such as fluid leakage, loss of pressure, or compromised structural integrity.

By conducting leak testing, manufacturers can identify and mitigate potential defects, such as porosity, cracks, that could serve as pathways for leaks. This helps in preventing costly recalls, repairs, or even catastrophic failures down the line. Ultimately, by implementing rigorous leak testing procedures, manufacturers can instill confidence in their products, ensure customer satisfaction, and uphold their reputation for delivering high-quality and reliable casting components.

Casting parts applications that require Leak test are:

- Engine Components: cylinder heads, engine blocks, and intake manifolds,

- Automotive Components: transmission housings, differential cases, and brake calipers etc.,

- Piping and Fittings: valves, flanges, and pipe fittings etc.,

- Pressure Vessels: tanks, boilers, and cylinders etc.,

- Medical Devices: orthopaedic implants, surgical instruments, and diagnostic equipment etc.,

- Aerospace Components: turbine blades, structural components, and fuel system parts etc.,

- Industrial Machinery: pumps, compressors, and hydraulic systems etc.,

Some of regular practice leak test methods are:

- Air Leak Testing: In air leak testing, the casting component is pressurized with a gas (such as air or nitrogen) to a specified pressure level, and then the pressure is monitored over a predetermined period. Any decrease in pressure indicates the presence of a leak. This method is suitable for detecting leaks in sealed or closed components.

- Vacuum Decay Testing: Vacuum decay testing is similar to pressure decay testing, but instead of pressurizing the component, it is placed under vacuum. Any increase in pressure within the component indicates the presence of a leak. This method is particularly effective for detecting leaks in components with internal voids or cavities.

- Bubble Leak Testing: Bubble leak testing involves applying a pressurized or vacuumed solution (such as soapy water or a specialized leak detection solution) to the surface of the casting component. Any leaks in the component will cause bubbles to form at the leak site, making it visible to the inspector. This method is suitable for detecting leaks in areas where direct access is possible.

- Water Leak Testing: Water leak testing is a most common method used to detect leaks in casting components. The component is pressurized with air, and dipped into water basin. Any leaks in the component will cause bubbles to form and can be identified by inspection engineer. This method is particularly effective for detecting leaks in critical components

- Helium Leak Testing: Helium leak testing is a highly sensitive method used to detect very small leaks in casting components. The component is pressurized with helium gas, and a sensitive helium leak detector is used to detect any helium escaping from the component. This method is particularly effective for detecting leaks in critical components where even small leaks can be detrimental.

Overcoming leak test failure for a part involves identifying the root causes of the failure and implementing corrective actions to address them

- Root Cause Analysis: Conduct a thorough investigation to identify the specific factors contributing to the leak test failure. This may involve reviewing manufacturing records, inspecting failed parts, analysing test data, and consulting with relevant personnel, such as process engineers, quality inspectors, and operators.

- Address Manufacturing Defects: If the leak test failure is attributed to manufacturing defects such as porosity, incomplete fill, cold shuts, or surface defects, take corrective actions to address these issues. This may include optimizing casting parameters, improving mold design, enhancing mold venting, adjusting injection pressure, or implementing better quality control measures during casting.

- Improve Design Considerations: Evaluate the design of the part and identify any features or geometries that may compromise sealing integrity. Make necessary design modifications to enhance sealing surfaces, eliminate sharp edges or corners, improve part alignment, and minimize potential leak paths. Utilize advanced design tools and simulation software to optimize part geometry and ensure proper functionality.

- Continuous Improvement: Implement a continuous improvement process to monitor, analyze, and address any recurring issues related to leak test failure. Regularly review test results, analyze trends, and solicit feedback from stakeholders to identify opportunities for further optimization and enhancement of manufacturing processes, materials, designs, and testing protocols.

Manufacturing defects such as shrinkage porosity, gas porosity, crack , cold shut etc plays a major role in leak test failure for part. These defects are generally detected once die is prepared and actual shop floor trails are conducted. By using defect prediction tools such as casting simulation software’s, designer can predict defects such as shrinkage porosity, gas porosity, crack , cold shut in casting even before die is prepared.

Leak testing can be virtually simulated using ADSTEFAN casting simulation software which is developed with NISSAN motors Japan along with ADSTEFAN team where designers can identify potential leak risk zones

Case study Leak Risk Assessment at initial design level using ADSTEFAN casting simulation software:

We have taken housing component and simulated water leak testing using ADSTEFAN casting simulation software.

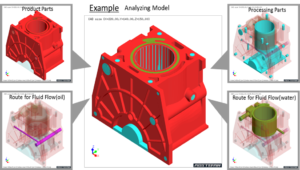

For simulation input of boundary conditions to be provided in ADSTEFAN such as oil path, water path and machining model of housing as shown in below fig a and considering all conditions, leak test is simulated.

Fig a: Leak test boundary conditions defined in ADSTEFAN

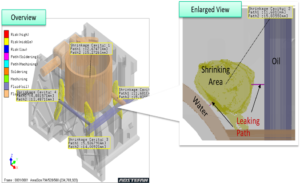

Leak prediction results using ADSTEFAN casting simulation software are displayed. Red region indicates high risk, Yellow region indicates medium risk location and blue region as low risk region as shown in fig b. ADSTEFAN will also show distance from predicted leak location to water path and oil path. Necessary actions should be taken during gating system design in order to mitigate risk assessment.

Fig b: Leak test results displayed in ADSTEFAN

Conclusion:

The use of ADSTEFAN casting simulation software for evaluating leak risk assessment at the initial design stage offers significant advantages in the casting industry. By simulating the casting process in detail, ADSTEFAN provides valuable insights into potential leak formation before actual production begins. The software’s ability to model fluid flow, thermal patterns, shrinkage, porosity, and solidification behavior enables engineers to identify critical areas of concern early in the design phase, thus preventing costly defects in the final product.

Through ADSTEFAN, manufacturers can perform gating optimization, and process parameter optimization to reduce the risk of leaks caused by issues such as incomplete filling, porosity, or thermal stresses. Additionally, the software’s capability to simulate and visualize these potential defects allows for more informed decision-making, resulting in improved casting integrity and reduced likelihood of defects during production.

By incorporating leak risk assessment in the design phase, manufacturers not only enhance the quality and performance of their castings but also reduce the need for extensive post-production testing and rework. Ultimately, the use of ADSTEFAN for leak risk evaluation contributes to more efficient, cost-effective, and reliable casting processes, leading to greater customer satisfaction and long-term product durability.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings