Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

ABSTRACT

Manufacturing industries are keen to upgrade to Industry 4.0/Die Casting 4.0 where industries to implement Machine Learning & Artificial Intelligence, Internet of Things (IoT) etc. in their production lines and converting these conventional lines into smart lines to meet customer requirements.

Simulation software providers are continuously improving software capabilities by constantly studying client expectations and requirements for intuitive operations. Implementation of Machine learning tool benefits Die casting industries by reducing costs of trails, produce sound casting and increases productivity.

Advance Defect Predication Tool (ADPT) is one such tool developed by Hitachi ICS Japan which will help users to analyze defects in less time and higher prediction accuracy using Machine Learning. In this paper, we will discuss with case study to understand defect prediction by Machine learning and advantages of Machining learning for diecasting industries.

Keywords: Die Casting 4.0, Casting Simulation, Machine Learning, Advance Defect Predication Tool (ADPT)

INTRODUCTION

Die casting is a manufacturing process in which, molten metal is poured or forced into steel molds having shape of required components. Components produced by die casting are of high accuracy. Die casting industries supply to major sectors like Aerospace, Automotive, Railways, Marine, Defense, General Engineering etc. These sectors use components with stringent quality requirements as end applications of these components are safety critical and die casting industries are working towards optimizing their manufacturing processes to meet customer requirements.

Die casting industries are amidst a significant transformation by application of digitization into manufacturing processes. This is Fourth Industrial Revolution where die casting industries are keen to implement Machine Learning & Artificial Intelligence, Internet of Things (IoT) etc. in their production lines and converting these conventional lines into smart lines to meet customer requirements.

INDUSTRIAL REVOLUTION

First Industrial Revolution – Revolved around mechanization of industries, steam power, waterpower. Manual manufacturing processes were replaced by machines. During first industrial revolution, movement of production from home to industries began.

Second Industrial Revolution – Revolved around mass production and assembly lines using electricity. This is also called technological revolution. This was a phase of rapid scientific discoveries, standardization, mass production and industrialization.

Third Industrial Revolution –This is also termed as Digital revolution. Invention of Internet, Computers and introduction of these systems in manufacturing industries led to third industrial revolution.

Fourth Industrial Revolution – In fourth industrial revolution or industry 4.0, the way companies manufacture, improve and distribute products is revolutionized by implementation of machine learning, artificial intelligence, Internet of Things (IoT) etc. Computers in manufacturing industries are inter-connected and these computers communicate with one another to ultimately make decisions without human involvement.

FOURTH INDUSTRIAL REVOLUTION – INDUSTRY 4.0 IN DIE CASTING INDUSTRY

Die casting industries are integrating Machine Learning, Artificial Intelligence, & IoT (Internet of Things) and Cyber Physical Systems into production lines which use computer-based algorithms to collect, monitor, control production lines and other processes, turning smart industry into a reality. This helps to create strong integration between machines, humans and information technology. Due to this integration, robust data analysis and in time corrective actions are possible which will help die casting industries in

- Detect deviations at initial stage

- Reduce wastage

- Low repair cost

- Improved Productivity

- Improved customer satisfaction

- Less environmental impact

CASTING SIMULATION

Casting mold flow simulation is used to simulate casting processes and predict casting defects, optimize gating design, reduce rejections, improve yield, reduce lead time and costs of development etc. Simulation software simulates casting process based on inputs provided by casting engineers, analyzes the inputs and provides output results. These output results are analyzed by simulation engineers and inputs are optimized to derive optimum output.

Defect prediction using casting simulation software during development stage will help casting industries to ensure sound castings during production.

BENEFITS OF CASTING SIMULATION

Simulation practice will help die casting industries in

- Reduced development costs due to least number of trials

- Less development lead time

- Less rejections

- Improved productivity

- Improved yield

- Improved casting quality

- Casting gating optimisation

MACHINE LEARNING:

Machine Learning (ML) is a type of Artificial Intelligence (AI) that allows software applications to predict outcomes more accurately. Machine Learning algorithms build a model based on sample data called master data, in order to make predictions or decisions without being explicitly programmed to do so.

For simple tasks, it is possible to program algorithms, telling the machine how to execute steps required to solve the problem on hand. For complex problems, it will be tedious task for humans to manually program algorithms and it can turn out to be more effective to help machine develop its own algorithm.

Machine learning has two objectives

- To classify data based on models which have already been developed

- To make future predictions based on developed models / datasets.

MACHINE LEARNING IN CASTING SIMULATION SOFTWARE

Casting simulation softwares are implementing Machine Learning which will help users in quick and more accurate defect prediction.

Advance Defect Prediction Tool – ADPT uses master data or database created by user to predict defect in target project by Machine Learning. Fig 1.1 shows ADPT analysis process flow.

Fig 1.1 – ADPT Analysis Process Flow

Defect prediction can be used for target projects of same cast alloy with different casting design and process parameters. Defect database for defects like flow marks, cold shuts, misrun, gas porosity, inclusions etc., can be created.

CASE STUDY FOR DEFECT PREDICTION USING MACHINE LEARNING:

We will discuss a case study to understand defect prediction by Machine Learning and advantages for die casting industries. To implement ADPT, products should be of same material grade and casting process.

Machine Learning uses data of defect type and defect intensity for prediction in target project.

First, we consider Project-A and simulate the model with below conditions.

- Maximum Die Temperature: 200 °C

- Average Die Temperature: 100 °C

- Low Die Temperature: 20 °C

Project-A cast material is AZ91D and is casted in High Pressure Die Casting process

Fig 1.2 – Project A for database creation

Fig 1.2 shows Project-A model for simulation analysis and defect master data creation.

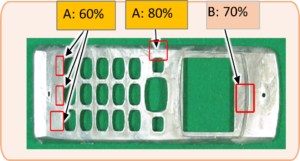

For first iteration with Condition-1, from simulation analysis and shop floor trials, we have observed Flow Marks and Cold shut defects in casting as shown in Fig 1.3. In this figure, defect A is flow marks and defects B is cold shut defects.

Fig 1.3 – Maximum die temperature defects

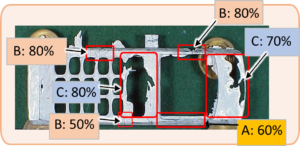

For second iteration with Condition-2, from simulation analysis and shop floor trials, we have observed Flow Marks, Cold shut and misrun defects in casting as shown in Fig_1.4. In this figure, defect A is flow marks, defect B is cold shut and defect C is misrun defects.

Fig 1.4 – Average die temperature defects

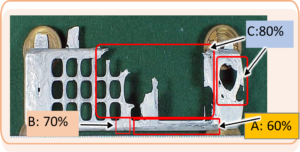

For third iteration with Condition-3, from simulation analysis and shop floor trials, we have observed Flow Marks, Cold shut and misrun defects in casting as shown in Fig_1.5. In this figure, defect A is flow marks, defect B is cold shut and defect C is misrun defects.

Fig 1.5 – Low die temperature defects

Next step is to identify defect location and create defect database in ADPT. Classification of defects, defect location in mesh model and defect intensity is input in a scale of 1 to 10, where 1 is low probability of defect and 10 is maximum probability of defect.

Now, with created database of Flow Marks, Cold Shut and Misrun in ADPT tool, through machine learning, we will use the database to predict defects in Project-B. Fig 1.6 shows Project-B chosen for defect prediction of material AZ91D, casted in high pressure die casting process.

Fig 1.6 – Project B for defect prediction

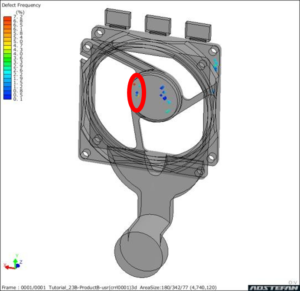

Fig 1.7 shows results of A-Flow Mark defect regions in Project-B through Machine Learning. Result shows, up to 7% of Flow Mark defect is possible at marked positions of casting.

Fig 1.7 – Flow Mark defect in Project-B

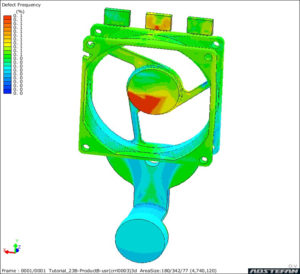

Fig 1.8 shows results of B-Cold Shut defect regions in Project-B through Machine Learning. Result shows low probability of cold shut defects in target project under current conditions.

Fig_1.8 – Cold Shut defect in Project-B

Fig 1.9 shows results of C-Misrun defect regions in Project-B through Machine Learning. Result shows, maximum value of legend is 0.1% and hence low probability of misrun defects in target project under current conditions.

Fig_1.9 – Mis Run defect in Project-B

CONCLUSIONS

Casting simulation softwares with Machine Learning technology help die casting industries to predict defects and implement corrective actions in less time and improve casting soundness. Implementation of Industry 4.0 techniques in die casting industries will ensure robust foolproof product quality in less lead time and low development costs.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings