Crack casting defect– Causes and Remedies & Casting crack prediction using ADSTEFAN casting simulation software

In the world of manufacturing, casting defects are one of the primary challenges that engineers and production teams face. Among these, crack defects are particularly troublesome as they can significantly compromise the integrity and quality of the final product. With the advancement of casting simulation software such as ADSTEFAN, addressing these defects has become more precise and efficient. In this article, we’ll explore what crack defects are, their causes, and how ADSTEFAN helps mitigate them through advanced simulation techniques.

What is a Crack Casting Defect?

A crack casting defect refers to fractures or fissures that occur within a casting during or after the solidification process. These cracks can appear as:

- Hot Cracks: Formed during solidification due to high thermal stress.

- Cold Cracks: Occur after the casting has cooled and are often a result of residual stress or external forces.

These defects can lead to reduced mechanical performance, compromised structural integrity, and increased scrap rates, making it essential to address them early in the production process.

Causes of Crack Casting Defects

Understanding the root causes of crack defects is crucial for their prevention. Common factors include:

- Thermal Stress: Rapid cooling and uneven temperature distribution can cause high thermal gradients, leading to cracks.

- Improper design considerations: Sharp corners, abrupt changes in section thickness, and inadequate gating systems can concentrate stress.

- Process Parameters: Improper pouring temperature, cooling rates, or mold material can exacerbate cracking risks.

- Material Properties: Some alloys are more prone to cracking due to their physical and thermal characteristics.

Remedies for Crack Defects in Investment Casting

To address crack defects, manufacturers can implement the following remedies:

- Optimize Cooling Rates: Ensure uniform cooling by using controlled cooling methods to achieve balanced thermal conductivity.

- Improve Casting Design: Eliminate sharp corners and abrupt changes in thickness. Use fillets and gradual transitions to distribute stress more evenly.

- Gating Optimization: Properly designed gating and riser systems reduce turbulence and stress during solidification.

- Process Parameters Optimization: Optimize pouring temperatures and shell preheating to reduce thermal shock.

- Select Suitable Materials: Use alloys with lower cracking susceptibility and better ductility to withstand thermal and mechanical stresses.

- Heat Treatment: Post-casting heat treatment can relieve residual stresses, reducing the likelihood of cold cracks.

- Use Simulation Software: Employ tools like ADSTEFAN to predict and mitigate potential defects during the design stages.

The Role of ADSTEFAN in Casting crack prediction

ADSTEFAN is a powerful investment casting simulation software that enables manufacturers to analyze and optimize their casting processes. Here’s how it helps mitigate crack defects:

- Thermal Analysis: ADSTEFAN provides detailed thermal simulations to identify hotspots and uneven cooling zones that could lead to thermal stress. By optimizing the cooling rate and distribution, manufacturers can reduce the risk of hot cracks.

- Stress Analysis: ADSTEFAN can simulate stress distribution within the casting during solidification and cooling. This allows engineers to predict areas prone to cracking and make design adjustments accordingly.

- Material Behavior Simulation: ADSTEFAN models the behavior of various alloys under different thermal and mechanical conditions, helping users choose the best material for their application.

- Gating Optimization: With its advanced modeling capabilities, ADSTEFAN helps optimize casting designs, including gating systems and riser placements, to minimize stress concentration points.

- Process Parameter Optimization: ADSTEFAN software allows for the simulation of different process parameters, such as pouring temperature and shell material properties, to determine the optimal settings for defect-free castings.

Benefits of Using ADSTEFAN for Crack Defect Prevention

- Reduced Scrap Rates: By identifying potential defects during the design phase, manufacturers can minimize scrap rates.

- Improved Product Quality: Simulation-driven insights lead to better structural integrity and mechanical performance.

- Cost Savings: Avoiding defects reduces rework, material costs, and production delays.

- Enhanced Productivity: Faster identification and resolution of issues streamline the manufacturing process

Defect Mapping on crack defect prediction using ADSTEFAN casting simulation software:

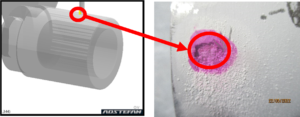

Figure – Visual Crack defect (right side) and predicted using ADSTEFAN casting simulation (left side).

The above figure illustrates the defect mapping of a crack casting defect in the investment casting process using ADSTEFAN simulation results. During shop floor trials, a crack defect was identified, as highlighted on the right-hand side of the figure. The root cause of the defect was traced to high stress concentrations at the crack defect location, as revealed by ADSTEFAN simulation results. This high stress at the highlighted location led to the formation of cracks in the casting, mirroring the findings observed during shop floor trials.

Conclusion:

Crack casting defects can be a major hurdle in achieving high-quality castings. However, with the use of advanced simulation software like ADSTEFAN, manufacturers can perform Casting crack prediction, analyze, and mitigate these defects effectively. By leveraging its powerful analytical tools, engineers can optimize their designs, materials, and processes to ensure defect-free castings, leading to cost savings and improved product performance.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings