Cold Shut Defect in HPDC- Casting defects and remedies

Cold shut casting defect in high-pressure die casting (HPDC) occur due to incomplete fusion of molten metal streams due to more temperature drop during the filling of die. This defect typically arises from a combination of factors related to the process, materials, and design. Understanding the root causes is crucial for implementing effective strategies to overcome Cold shut casting defect.

We have listed out some of Cold shut Casting defects and remedies:

Inadequate Metal Flow:

- Cause: When the metal flow is not properly controlled, two streams of molten metal may meet at an temperature below solidus temperature, leading to incomplete fusion and leads to formation of cold shut casting defect.

- Overcome: Optimizing process parameters such as injection speed, pressure, and melt and die temperature helps ensure proper metal flow and fusion. Adjusting these parameters based on the specific requirements of the casting can minimize the occurrence of cold shuts.

Improper Gate and Runner Design

- Cause: Inefficient gating and runner systems can result in turbulence metal flow, increasing the likelihood of cold shuts at junctions where metal streams meet.

- Overcome: Gating optimization to facilitate smooth and uniform metal flow can mitigate the risk of cold shuts. Proper gating design, including the use of multiple gates or well-designed runners, can promote better distribution of molten metal and reduce the chances of Cold shut casting defect.

Die Design Issues

- Cause: Inadequate venting, insufficient cooling, or improper die geometry can contribute to uneven filling and premature solidification, leading to cold shut defects.

- Overcome: Enhancing die design by incorporating effective venting systems, optimizing cooling channels, and ensuring proper geometry helps maintain uniform metal flow and temperature distribution. Well-designed dies reduce the likelihood of premature solidification and improve fusion at critical junctions.

Metal Temperature and Alloy Composition:

- Cause: Variations in metal temperature or alloy composition can affect the fluidity and solidification behavior of the molten metal, influencing the formation of cold shuts.

- Overcome: Monitoring and controlling metal temperature within the die casting machine, and using alloys with suitable properties, help prevent premature solidification and ensure proper fusion. Maintaining consistent metal temperature throughout the casting process minimizes the risk of defects.

By addressing these underlying causes and implementing appropriate measures, such as Gating optimization and process parameters optimization enhancing design elements, and implementing quality control practices, manufacturers can effectively overcome cold shut defects in high-pressure die casting processes, ensuring the production of high-quality components.

Preventive solutions through ADSTEFAN die casting simulation software:

ADSTEFAN high pressure die casting simulation software serves as a powerful tool for predicting and preventing defects like cold shuts. By using advanced algorithms and computational fluid dynamics (CFD) simulations, casting simulation assist design engineers can access flow conditions of molten metal in cavity whether for given conditions and gating design any temperature drop is detected in cavity.

- Predictive Modelling: ADSTEFAN Casting simulation software enables engineers to create virtual designs of gating system, allowing them to simulate the entire manufacturing process from shot sleeve filling to solidification. By analysing factors such as fluid flow, temperature distribution, and solidification patterns, engineers can identify potential areas of concern and implement corrective measures proactively.

- Gating Optimization and Parameter Optimization: Through iterative simulations, casting engineers can fine-tune process parameters such as pouring temperature, pressure parameters and gating system design to minimize the risk of defects like cold shuts. This iterative approach empowers manufacturers to optimize casting processes for maximum yield and quality while minimizing scrap and rework.

- Cost Reduction: By identifying and addressing casting defect early in the design phase, ADSTEFAN casting simulation helps to eliminate need for physical shop floor trails. Moreover, by optimizing process parameters, manufacturers can achieve higher casting yields and reduce material wastage, resulting in significant cost savings over time.

Case study on predicting cold shut casting defect using ADSTEFAN hpdc simulation software:

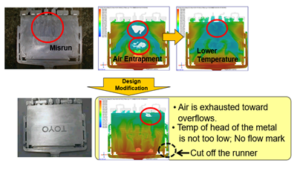

Fig a. Cold shut/ Misrun defect comparison with actual and ADSTEFAN simulation results

Above are images provide comparison between ADSTEFAN casting simulation results with actual castings. As observed, there is a temperature drop in the highlighted region where molten metal converges from multiple ingates, leading to the formation of a cold shut defect. After design modification where side gates are removed and metal flow is only through center gating , observed better temperature distribution. By using casting mold flow simulation- ADSTEFAN, temperatures can be measured at any location and time during the mold filling process. This capability gives gating designers a thorough insight into the temperature difference of molten metal during pouring, enabling them to enhance casting yield and accurately predict cold shut casting defect even before the die is manufactured. Consequently, this approach aids in achieving thermal balance in die casting, ultimately saving energy, lowering production costs, and reducing development lead times.

Conclusion:

In HPDC, the cold shut defect remains a persistent challenge, compromising the quality and integrity of cast components. However, using of ADSTEFAN casting simulation technology, die casters can now predict cold shut defects even before pattern is developed saving material, time and cost. As we continue to push the boundaries of innovation, ADSTEFAN stands acts as a key tool of modern manufacturing, driving excellence and efficiency in the quest for flawless castings.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings