Casting rejection can be controlled, Here are important tips

In every foundry, one of the most persistent challenges is high casting rejection rates due defects. These rejections not only increase production cost but also impact delivery schedules and customer satisfaction. The good news is — casting rejections can be effectively controlled through a systematic, data-driven approach. Let’s explore how industries can achieve this.

- Identify and Classify Casting Defects

The first step towards rejection control is understanding the type and cause of defects. Common casting defects include:

- Shrinkage porosity

- Cold shuts

- Misruns

- Gas porosity

- Inclusions

- Hot tears or cracks

By categorizing these defects based on visual inspection, radiography, or metallurgical analysis, foundries can focus on the root cause rather than the symptom.

- Use of Casting Simulation software for Gating and Process Validation

Modern casting simulation software such as ADSTEFAN allows engineers to predict defects before actual production.

Simulation helps in:

- Visualizing mold filling and solidification behavior

- Identifying hot spots and shrinkage-prone zones

- Optimizing gating and riser design

- Evaluating cooling line layouts and mold materials

- By validating the design virtually, foundries can avoid costly trial-and-error and achieve first-time-right castings.

Case study:

In this case study we have considered Sand Casting process with Material –Stainless steel, Casting Weight – 61.50 Kg , Bunch Weight – 77.38 kg and Yield – 79.47 %.

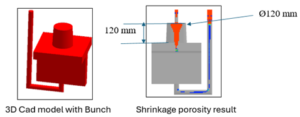

Shrinkage results as shown in above figure indicated shrinkage inside casting section. Root cause of shrinkage in casting is improper consideration of riser.

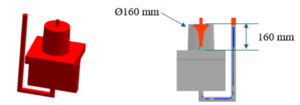

Above the result for optimized riser dimension Riser dia 120mm to 160mm and height 120mm to 160mm, and observed proper feeding of riser and the shrinkage porosity eliminated in casting area.

Thus root cause of rejection is identified as shrinkage porosity and by optimizing gating design, shrinkage porosity is avoided and rejections are controlled.

- Standardize Process Parameters

Consistency is the key to quality. Variations in melt temperature, pouring speed, die temperature can drastically affect casting integrity. Through ADSTEFAN casting simulation validation of process parameters and its effect on rejection can be studied. Implement process control sheets (PCS) and SPC techniques ensures that every batch follows the same optimized parameters, minimizing defect variations.

- Continuous Monitoring and Feedback Loop

Implementing real-time process monitoring systems allows operators to track deviations in parameters such as temperature, pressure, or fill time. Integrating quality feedback loops from inspection data back to the design and simulation team ensures continuous improvement across the production cycle.

- Skill Development and Foundry Training

Often, casting defects arise due to improper handling, poor gating assembly, or incorrect core setting. Regular training for foundry operators, tool designers, and quality engineers plays a crucial role in maintaining standards and improving yield.

- Embrace Data-Driven Decision Making

Adopting digital foundry practices — where simulation data, sensor feedback, and rejection reports are analyzed together — enables smarter decision-making. This approach helps in trend identification, root cause analysis, and predictive maintenance, all of which contribute to rejection reduction.

Conclusion

Reducing casting rejection is not a one-time activity — it’s a continuous improvement journey. By combining casting simulation technology such as ADSTEFAN casting simulation software, process standardization, and skilled workforce, foundries can significantly cut down rejections, improve yield, and enhance profitability.

With the right digital tools and engineering mindset, achieving “Zero Defect Casting” is no longer a dream — it’s an achievable reality.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings