Casting defects and remedies: Eliminating Warpage Casting Defect using ADSTEFAN Casting simulation software

Warpage casting defect stands out as a significant concern that leads to casting rejection. In this article, we discuss in detail Casting warpage prediction using sand casting simulation software – ADSTEFAN

Understanding Warpage Casting Defect:

Warpage, also known as distortion refers to the deviation from the intended shape or geometry of a casting. This casting defect often happens as bowing, twisting, or curvature along the length or width of the component. Warpage not only compromises the dimensional accuracy of the casting but also affects its functional performance and structural integrity leading to casting rejection. If this casting defect is not addressed in the casting process, higher machining tolerances have to be given which would increase the product cost!!.

Causes of Warpage Defects:

- Non-Uniform Cooling: During the casting process, uneven cooling rates can lead to differential contraction across the casting, resulting in residual stresses and warp hence casting defect. Factors such as mold geometry, material properties, and cooling conditions contribute to non-uniform cooling.

- Mold Design and Rigidity: The design of the sand mold, including its geometry, gating system, and venting arrangement, influences the distribution of stresses during solidification. Inadequate support or insufficient rigidity in the mold structure can lead to deformation under the thermal and mechanical loads exerted by the molten metal.

- Pouring and Cooling Conditions: Improper pouring, such as excessive pouring temperatures or rates, can cause thermal gradients and residual stresses within the casting, contributing to warpage casting defect. Similarly, inadequate cooling measures or premature removal of the casting from the mold can result in uneven cooling and distortion.

- Process Parameters: Various parameters of the casting process, such as mold preheating, pouring temperatures and solidification time, impact the occurrence of warpage defects. Optimizing these parameters to achieve uniform solidification and minimize thermal gradients is essential for mitigating warpage.

- Material Selection: The choice of casting material plays a crucial role in determining its susceptibility to warpage. Metals with high thermal expansion coefficients or significant shrinkage upon solidification are more prone to distortion.

Role of ADSTEFAN sand casting simulation in Casting warpage prediction:

ADSTEFAN sand casting simulation has emerged as a powerful tool for Casting warpage prediction in sand casting. By simulating the entire casting process digitally, engineers can identify potential sources of distortion and implement corrective measures proactively. Here’s how ADSTEFAN simulation helps in addressing the causes of warpage defects:

- Thermal Analysis: ADSTEFAN casting defect simulation software allows engineers to simulate the heat transfer and solidification behavior of the casting, enabling the prediction of temperature gradients and thermal stresses. By optimizing mold design and cooling strategies based on thermal analysis, engineers can minimize the risk of warpage casting defect.

- Mold Design and Gating Optimization: Through ADSTEFAN casting defect simulation software, engineers can iteratively optimize mold geometry, Gating optimization, and venting placement to minimize stress concentrations and ensure uniform cooling. By incorporating features such as chill, risers, and directional solidification techniques, the risk of warpage can be significantly mitigated.

- Process Parameter Optimization: ADSTEFAN enables engineers to explore a wide range of process parameters, such as pouring temperature, pouring rate, and mold preheating, to identify the optimal conditions for Casting warpage prediction. By conducting virtual experiments and sensitivity analyses, engineers can optimize the casting process and reduce the propensity for distortion.

- Material Characterization: ADSTEFAN facilitates the evaluation of different casting materials and their corresponding mechanical properties, thermal expansion coefficients, and solidification behavior. By selecting materials with good characteristics and simulating their response to casting conditions, engineers can reduce the likelihood of warpage casting defect.

- Casting defects and remedies: In cases where warpage casting defect occurs, ADSTEFAN can be used to analyze the root causes. Whether through redesigning the mold geometry or gating design, adjusting process parameters, or post-casting heat treatment, simulation empowers engineers to address warpage issues effectively.

Defect Prediction of Warpage using ADSTEFAN casting simulation software:

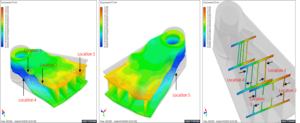

Figure a – Warpage defect prediction using ADSTEFAN simulation software

Above figure(a) demonstrates warpage casting defect using sand casting simulation software – ADSTEFAN. Root cause of casting defect is identified as high distortion due to improper/insufficient support ribs consideration at warpage location are observed in casting in ADSTEFAN results. Due to this high distortion development at highlighted location, cracks defect is formed in casting and same phenomenon is observed in shop floor trails.

Conclusion:

Warpage casting defect pose a significant challenge in sand casting, impacting the dimensional accuracy and structural integrity of cast components. However, using ADSTEFAN – Casting warpage prediction technology, engineers can predict, and necessary preventive actions can be taken to resolve warpage defects. By using ADSTEFAN casting simulation techniques to optimize mold and gating design, material selection, and process parameters, manufacturers can produce high-quality castings with minimal distortion. As simulation tools continue to evolve, they promise to play a important role in enhancing the efficiency and reliability of sand-casting processes, driving innovation in manufacturing across industries

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings