Case study crack defect prediction in sand casting using Adstefan casting simulation software

Introduction:

Crack is one of the most critical and costly defects in sand casting. It can lead to product failure, increased scrap rates, and production delays. In this case study, we explore how ADSTEFAN casting simulation software was used to crack defect prediction and prevent cracking in a complex sand-casting component, improving yield and reducing post-processing time.

What is Crack –

Casting cracks are defects that can occur during the casting process in which cracks or fractures form in the surface or interior of the part. These cracks can cause problems with the strength, durability, and overall quality of the finished product

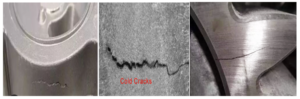

Figure – Hot crack, cold crack and fatigue crack from left to right

Here a more detailed to look a crack defect in casting

There are three type of crack defects in casting

- Hot Crack

- Cold Crack

- Thermal Fatigue Cracks

- Hot Crack:

Occurs when the casting is still hot and under pressure which causes small hairline cracks which are visible in the casting after it has been cooled.

- Cold Crack:

Develops after the metal casting has cooled and the stress builds up due to contraction that results from cooling down.

- Thermal Fatigue Crack:

This is caused due to metal expansion and contraction due to extreme temperature changes which create elongated cracks in the casting.

Causes of crack in casting:

- Complex geometry with thick and thin section in casting

- Uneven cooling and solidification

- High mechanical stress developed inside casting

- Gating System issue

Remedies for crack in casting:

- Maintain uniform wall thickness

- Use chills to control cooling rate

- Provide fillet and avoid sharp edge

Crack defect prediction in sand casting using Adstefan casting simulation software

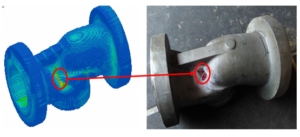

In foundry producing high-strength steel components was facing recurring hot crack and cold cracking issues in a valve body casting. Foundry persons based on experience changed gating and riser design, cracks continued to appear

By using Adstefan casting simulation software we simulated

- Mold filling analysis

- Solidification analysis

- Thermal stress analysis and crack and defect visualization

Key finding from using casting simulation software

- By mold filling simulation we have checked for casting defects such as cold shut, misrun , blowholes, sand erosion, sand inclusion and found less chances of above mentioned filling related defects.

- By solidification analysis we found uneven solidification due to improper placement of risers and gating design leading to shrinkage and stress in the casting.

- By thermal stress analysis we have checked high stress zone (Above the ultimate stress of that material grade) due to uneven solidification in casting

Root cause of defect:

Uneven solidification due to improper riser and gating considered leads to stresses found at crack location above material ultimate tensile stress leading to crack defect in casting

Above the image shows the higher stress zone inside the casting at highlighted area.

Remedy for implemented using simulation

- Riser design change to improve feeding and reduce shrinkage stress

- Uniform Cooling by implementing chills at thick section

Result After Implementation

- Crack Eliminated in final casting

- Rework reduced

Conclusion:

This case study highlights the effectiveness of ADSTEFAN casting simulation software in Crack Defect prediction and remedying in sand casting. By identifying thermal and mechanical stress zones, foundries can optimize their designs before production, saving time, cost, and material.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings