Blow Hole Defect Prediction in Low Pressure Die Casting: Strategies and Solutions with ADSTEFAN air entrapment prediction software

Introduction:

In LPDC process symmetrical parts of intricate designs can be cast within less cycle time with more yield. However, the presence of blow hole defects can affect product quality and increased manufacturing costs. However, with a deeper understanding of their causes and with advanced air entrapment simulation predictions like ADSTEFAN, we can overcome blow hole defect in casting.

Exploring the Causes of Blow Hole Defects:

Blow hole defects, characterized by the presence of gas voids or cavities within castings. Causes of blow hole defect can include:

- Inadequate Venting: Insufficient venting of the die cavity can stop the escape of trapped gases, leads to the risk of blow hole formation.

- Trapped Air: Entrapped air within the die cavity or the molten metal itself can lead to the formation of blow holes during solidification.

- Gas Evolution: Certain alloy compositions may undergo gas evolution reactions, releasing trapped gases that form bubbles within the casting.

Strategies for Overcoming Blow Hole Defects:

Addressing Blow hole defects requires an approach of both process and design optimization. Some strategies to consider include:

- Enhancing Venting: Optimizing venting systems within the die cavity helps facilitate the escape of trapped gases during the casting process, reducing the likelihood of blow hole formation.

- Alloy Selection: Choosing alloy compositions with minimal gas evolution tendencies can mitigate the risk of blow hole defects, enhancing casting integrity.

- Controlling Metal Temperature: Maintaining control over metal temperature throughout the casting process minimizes the formation of gas bubbles and promotes smoother solidification.

- Optimizing Gating Design: Well-designed gating systems promote uniform metal flow and minimize turbulence, reducing the chances of gas entrapment and blow hole formation.

ADSTEFAN Casting Simulation Software for air entrapment prediction:

ADSTEFAN aluminium die casting simulation software emerges useful tool for predicting and mitigating blow hole defects in LPDC processes. By performing LPDC Simulation the entire casting process in a virtual environment, ADSTEFAN offers invaluable insights into gas flow dynamics, temperature gradients, and solidification behavior. Its advanced computational fluid dynamics (CFD) capabilities enable engineers to visualize potential blow hole formation and iteratively optimize process parameters to prevent defects.

ADSTEFAN prediction of blow hole defects by:

- Evaluating Venting Efficiency: By simulating gating optimization with venting systems, ADSTEFAN helps assess their effectiveness in expelling trapped gases, guiding improvements for enhanced venting performance.

- Optimizing Process Parameters: Through virtual experimentation, ADSTEFAN allows engineers to optimize process parameters such as gating optimization, metal temperature, and alloy composition to minimize blow hole defects.

Case study – Blow holes prediction using Low pressure die casting simulation process in ADSTEFAN:

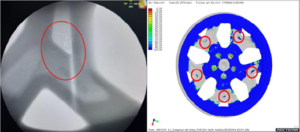

- Blue color – air in the component

- Transparent color – complete liquid metal

- Green color – mixture of liquid metal and air

Above figure demonstrates defect mapping of blow holes defect for LPDC process with ADSTEFAN die casting simulation software. We have simulated flow pattern and blue color in image represents air inside cavity during filling and transparent color represents already filled molten metal at these areas. The root cause of defect is identified as air pocket isolations during filling which is highlighted are observed in casting in ADSTEFAN Low pressure die casting simulation. Due to this air pocket isolation is observed in cavity which leads air gets entrapped between the molten metal and thus forms as Gas porosity in casting and same phenomenon is observed in shop floor trails.

Preventive action taken on component by gating optimization and provide air vents in location where air pocket isolated and thus blow holes defect is controlled. This gating optimization is carried out in ADSTEFAN casting simulation software and best gating design, and vent locations are considered in shop floor trails thus leading to elimination of blow holes defect in shopfloor. By performing corrective actions using ADSTEFAN casting simulation software, we can reduce shop floor trails, production, and development time of component.

Conclusion:

Blow hole defects pose a challenge in low-pressure die casting, but with the right strategies and tools at hand, they can be effectively controlled. Using ADSTEFAN casting simulation software, offering precise prediction capabilities and empowering manufacturers to optimize processes for flawless castings. By using ADSTEFAN’s insights, manufacturers can overcome blow hole defects, ensuring the production of high-quality castings that meet the most stringent standards of performance and reliability.

Recent Posts

- LPDC simulation of alloy wheel to predict the defects produced due to improper die heating.

- Implementing Machine learning on Defect prediction for Investment casting through ADSTEFAN casting simulation software

- Methods for Indian Casting Manufacturers to Overcome Fluctuating Raw material price

- Casting rejection can be controlled, Here are important tips

- Die Casting 4.0 – Casting Defect Prediction by Machine Learning for Die casting industries using Casting Simulation Software

- Types of Cooling Lines and Thermal balancing die casting Using ADSTEFAN Casting Simulation Software for Casting gating optimisation & Cooling lines optimization

- Yes! We can perform air entrapment prediction and overcome by air entrapment simulation using ADSTEFAN casting simulation software. Here is how we can do

- Are You Facing Challenges in Utilizing Casting Simulation Software? Here’s How to Overcome Them

- Better practice for effective utilization of simulation software

- More Yield, Fewer Defects – How ADSTEFAN helps to Transforms Gating Design! – Case study on Steel Valve body castings