Aluminum die casting simulation software for defect prediction and gating optimisation

Aluminium die casting industry used in production of intricate complex shaped products, is expected to

flourish with boom electric vehicles (EV s). During die casting, several defects such as shrinkage porosity, gas

porosity, hot tear, cold shut, air entrapment, and so on occur. This will reduce the quality and productivity of

cast component. By a adopting simulation based methodology, die design (gating) and process design can be

optimised to reduce (and nearly eliminate) defects and increase productivity. Metal casting simulation

software such as ADSTEFAN, can be very useful to conduct such gating and process optimisation.

Using casting simulation software ADSTEFAN, engineers can predict defects such as turbulent filling, cold shut,

misruns, air entrapment, solidification related predictions such as solidification pattern, shrinkage porosity,

thermal stress related defects such as cracks, warpage and distortion.

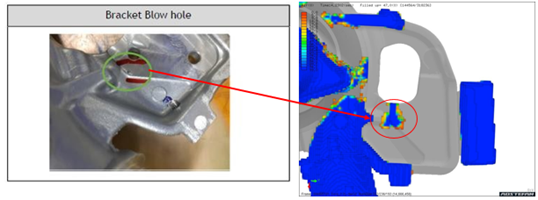

Figure-1 shows an aluminum cast component with gas porosity defect. Adjacent figure shows the prediction

of gas porosity defect using adstefan for die casting simulation.

Figure-1: Gas Porosity defect prediction in die casting

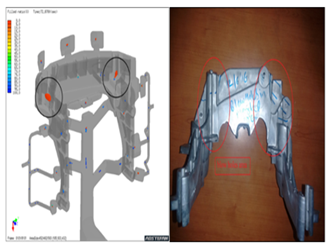

Figure-2 below shows the shrinkage porosity in a high pressure die casting (HPDC) (right side picture

cast component). Left side shrinkage porosity prediction using simulation software ADSTEFAN.

Figure-2: (left) Shrinkage porosity defect prediction using casting simulation software in high

pressure die casting (HPDC), (right) shrinkage porosity in the cast component.

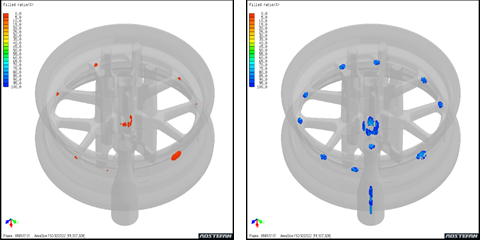

Figure-3 shows the shrinkage porosity prediction using simulation of a low pressure die casting

(LPDC) of alloy wheels.

Figure-3: Shrinkage porosity prediction Low Pressure Die Casting (LPDC) of alloy wheels

In all cases, aluminium die casting process and gating design was optimised by using simulation

software ADSTEFAN.

For more details of how casting simulation can help you, contact casting@pro-sim.com or visit: http://www.castingsimulation.in/index.php

Recent Posts